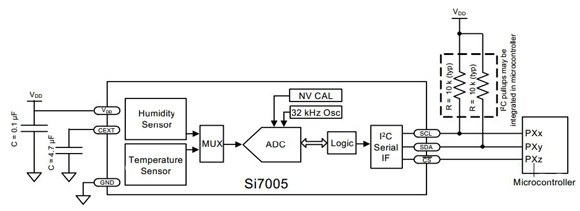

A new generation of devices is emerging that integrates temperature and humidity sensing alongside data converters and logic with sophisticated calibration. Integrating the sensor can reduce the complexity and reliability of the system and provide more protection for sensitive electronic designs, as demonstrated by the Si7005 from Silicon Labs.

Developments in CMOS process technology are opening up new opportunities for the designers of embedded systems. Adding low-K polymeric dielectrics into the design means capacitive humidity sensors can be built alongside integrated temperature sensors along with integrated heating elements. This combination provides a powerful way to reduce the size and complexity of a system.

However, this comes with new design considerations. While previous protection and calibration of the sensor was handled in a discrete part, now it is part of a more complex logic design. Although this has advantages for the calibration, it has challenges for the designers, especially for the new generation of devices that integrate both temperature and humidity sensors. There are also new ways for the parts to be specified, with the specification of the accuracy and measurement margins.

Designers now have to consider protection of the device during the reflow process, taking baking and hydrating of the device into account in the development of the system and how this impacts the accuracy of the sensor measurements both immediately and in the longer term.

The Si7005 from Silicon Labs offers an accurate, low-power, factory-calibrated digital solution for measuring temperature, humidity, and dew point in applications ranging from air conditioning and asset tracking to industrial and consumer platforms.

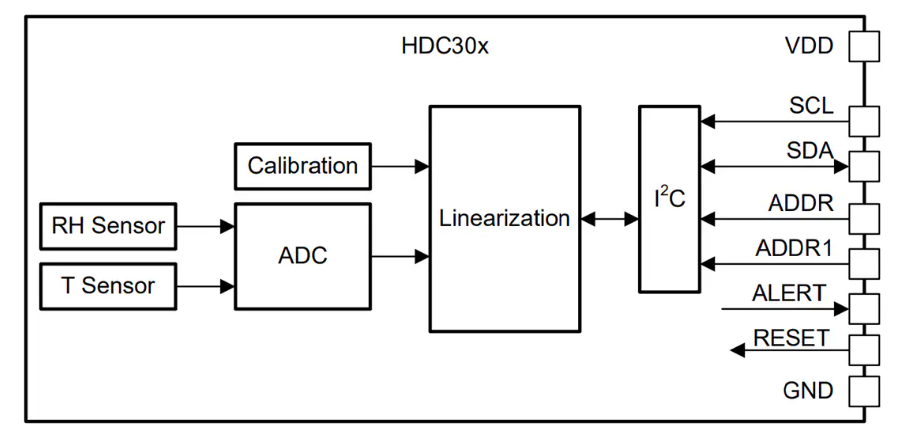

The monolithic CMOS digital relative humidity and temperature sensor integrates temperature and humidity sensor elements, an analog-to-digital converter, signal processing, calibration data, and an I2C host interface. The patented use of industry-standard, low-K polymeric dielectrics for sensing humidity enables the construction of a low-power, monolithic CMOS sensor with low drift and hysteresis, and excellent long-term stability.

Both the temperature and humidity sensors are factory-calibrated and the calibration data is stored in the on-chip non-volatile memory. This ensures that the sensors are fully interchangeable, with no recalibration or software changes required.

Environmental protection is a key consideration for applications that use a humidity and temperature sensor, so an optional factory-installed protective cover offers a low profile, convenient means of protecting the sensor during assembly (for example during reflow soldering), and throughout the life of the product, excluding hydrophobic or oleophobic liquids and particulates.

While the Si7005 is largely a conventional mixed-signal CMOS integrated circuit, relative humidity sensors in general, and those based on capacitive sensing using polymeric dielectric, have unique application and use requirements that are not common to conventional non-integrated devices. The main issues are the need to protect the sensor during board assembly, and the need to subsequently rehydrate the sensor. There is also the need to protect the sensor from damage or contamination during the product lifecycle, and designers have to consider the impact of prolonged exposure to extremes of temperature and/or humidity and their potential effect on sensor accuracy. This is coupled with the issues of calibration and the effects of humidity sensor ‘memory’, as well as the need to apply temperature correction and linearization to the humidity readings.

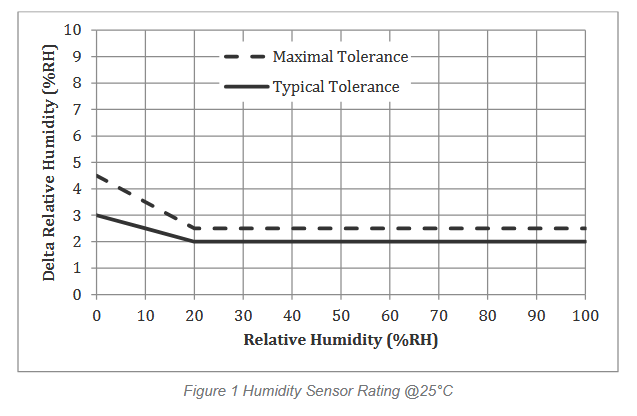

Relative humidity sensor accuracy

To determine the accuracy of a relative humidity sensor, it is placed in a temperature and humidity-controlled chamber. The temperature is set to a convenient fixed value (typically 30°C) and the relative humidity is swept from 20% to 80% and back to 20% in the following steps: 20% – 40% – 60% – 80% – 80% – 60% – 40% – 20%. At each set-point, the chamber is allowed to settle for a period of 30 minutes before a reading is taken from the sensor. Prior to the sweep, the device is allowed to stabilize to 50%RH. The RH accuracy is defined as the average of the two data points at each relative humidity set-point. In this case, the sensor shows an accuracy of 0.25%RH.

This provides an accuracy specification that includes unit-to-unit and lot-to-lot variation in non-linearity compensation, the accuracy of the factory calibration, and the margin for shifts that can occur during solder reflow (compensation for shift due to reflow is included in the linearization procedure below).

However, there are some limitations to the accuracy specification. It does not include hysteresis effects, which are typically ±1%, nor does it cover effects from long-term exposure to very humid conditions. Contamination of the sensor by particulates and chemicals can also have an effect. While the specification does not include variations due to temperature, once the temperature compensation is applied, the humidity readings will typically vary by less than ±0.05%/°C.

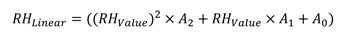

The capacitive relative humidity sensor in the Si7005 also needs linearization, and the accuracy specification applies after correction of non-linearity errors. The recommended linearization technique is to correct the measured relative humidity value with a second-order polynomial; the linear relative humidity (RH) value is calculated from the formula in Figure 2.

Figure 2: Linearization of the relative humidity value, where RHLinear is the corrected relative humidity value in %RH, RHValue is the uncorrected (measured) relative humidity value in %RH, and A2, A1, and A0 are unit-less correction coefficients derived through characterization of Si7005s by Silicon Labs; their values depend on whether compensation for a typical solder reflow is required.

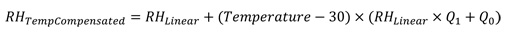

The humidity sensor is calibrated at a temperature of 30°C as the sensor will give the most accurate relative humidity readings. For relative humidity measurements at other temperatures, the RH reading from the Si7005 must be compensated for the change in temperature relative to 30°C, using the values from the integrated temperature sensors. This makes the compensation process relatively simple and self-contained within the device.

Temperature compensated relative humidity readings can be calculated from the formula in Figure 3.

Figure 3: Temperature compensation for the Si7005, where RHTempCompensated is the temperature compensated relative humidity value in %RH and RHLinear is the linear corrected relative humidity value in %RH. Temperature is the ambient temperature in °C as measured by the Si7005 on-chip temperature sensor and Q1 and Q0 are unit-less correction coefficients derived through characterization of Si7005s by Silicon Labs. This temperature compensation is most accurate in the range of 15–50°C.

The Si7005 relative humidity sensor contains an integrated, resistive heating element that may be used to raise the temperature of the humidity sensor. This element can be used to drive off condensation or to implement dew point measurement when the Si7005 is used in conjunction with a separate temperature sensor such as another Si7005.

The heater can be activated by setting the D1 HEAT bit in the CONFIG register (register 0x03). Turning on the heater will reduce the tendency of the humidity sensor to accumulate an offset due to "memory" of sustained high humidity conditions. When the heater is enabled, the reading of the on-chip temperature sensor will be increased.

Hysteresis

The moisture absorbent film (polymeric dielectric) of the humidity sensor will carry a memory of its exposure history, particularly its recent or extreme exposure history. A sensor exposed to relatively low humidity will carry a negative offset relative to the factory calibration, and a sensor exposed to relatively high humidity will carry a positive offset relative to the factory calibration. This factor causes a hysteresis effect, the difference in %RH between the maximum absolute error on the decreasing humidity ramp and the maximum absolute error on the increasing humidity ramp at a single relative humidity set-point. This is expressed as a bipolar quantity relative to the average.

Prolonged exposure to high humidity will result in a gradual upward drift of the RH reading. The shift in sensor reading resulting from this drift will generally disappear slowly under normal ambient conditions. The amount of shift is proportional to the magnitude of relative humidity and the length of exposure. In the case of lengthy exposure to high humidity, some of the resulting shift may persist indefinitely under typical conditions. It is generally possible to substantially reverse this effect by baking the device.

Si7005 devices are shipped, like most ICs, vacuum-packed with an enclosed desiccant to avoid any drift during storage, as well as to prevent any moisture-related issues during solder reflow. Devices should be soldered using reflow and a ‘no clean’ solder process, as a water or solvent rinse after soldering will affect accuracy.

The measured humidity value will generally shift slightly after solder reflow. This shift is accounted for when using the linearization procedure given above. After soldering, the Si7005 should be allowed to equilibrate under controlled RH conditions (room temperature, 45–55%RH) for at least 48 hours to reach rated accuracy. During soldering, it is recommended that a protective cover of some kind be in place such as Kapton polyimide tape. Hot air rework is not recommended and soldering iron touch-up is possible if flux is not needed and care is taken to avoid excessive heating. If rework is required, the part can be removed by hot air and a new part soldered on by reflow.

Alternatively, Si7005s may be ordered with a factory fitted, solder-resistant protective cover which can be left in place for the lifetime of the product, preventing liquids, dust or other contaminants from coming into contact with the polymer sensor film.

Protecting the sensor

When the sensor operates on the principle of measuring a change in capacitance, any changes to the dielectric constant of the polymer film will be detected as a change in relative humidity. Therefore, it is important to minimize the probability of contaminants coming into contact with the sensor. Dust and other particles, as well as liquids can affect the RH reading. It is recommended that a filter cover be employed in the end system that blocks contaminants, but also allows water vapor to pass through. Depending on the needs of the application, this can be as simple as plastic or metallic gauze for basic protection against particulates, or something more sophisticated such as a hydrophobic membrane providing up to IP67 compliant protection.

As mentioned earlier, Si7005s may be ordered with a factory fitted, solder-resistant cover, which can be left in place for the lifetime of the product. It is very low profile, hydrophobic and oleophobic, and excludes particulates down to 0.35 microns in size. The sensor should also be protected from direct sunlight to prevent heating effects as well as possible material degradation.

After exposure to extremes of temperature and/or humidity for prolonged periods, the polymer sensor film can become either very dry or very wet; in each case the result is either high or low relative humidity readings. Under normal operating conditions, the induced error will diminish over time. From a very dry condition, such as after shipment and soldering, the error will diminish over a few days at typical controlled ambient conditions, for example, 48 hours of 45 ≤ %RH ≤ 55. However, from a very wet condition, recovery may take significantly longer. To accelerate recovery from a wet condition, a bake and hydrate cycle can be implemented. This operation consists of baking the sensor at 125°C for over 12 hours, followed by hydration at 30°C in 75%RH for 10 hours. Following this cycle, the sensor will return to normal operation in typical ambient conditions after a few days.

Long term drift/aging

Over long periods of time, the sensor readings may drift due to aging of the device. Standard accelerated life testing of the Si7005 has resulted in the specifications for long-term drift shown in Table 4 and Table 5 of the datasheet. This contribution to the overall sensor accuracy accounts only for the long-term aging of the device in an otherwise benign operating environment and does not include the effects of damage, contamination, or exposure to extreme environmental conditions.

Development support

A suite of hardware and software development tools for testing, characterization, prototyping, and software development is available to support the Si7005.

The Si7005USB-DONGLE Evaluation Kit comes with everything developers need to demonstrate and evaluate the Si7005. The board plugs into a PC via a USB socket and has a connector for adding the Si7005USB-EVB. This is a small daughter card that permits evaluation of the Si7005 at the end of a flex cable.

The Si7005EVB-UDP is a small daughter card for evaluating the Si7005 in conjunction with certain Unified Development Platform (UDP) components such as the C8051F960 Ultra-Low-Power Microcontroller Development Kit. It plugs directly into UDP MCU cards for fast prototyping and software development. Alongside the Si7005, there is also a connector for adding a Si7005-EVB via its flex cable, allowing the user to place the Si7005 in a temperature/humidity chamber or a product prototype.

The Si7005EVB-UDP-F960 Development Kit combines the C8051F960 Ultra-Low-Power Microcontroller Development Kit and the Si7005EVB-UDP daughter card with data-logger demonstration code. It is a complete package designed to support hardware and software development using the Si7005 and Silicon Labs’ ultra-low-power MCUs. It ships with example software that implements a portable, battery-powered data logger or asset tracker.

Figure 4: The development systems for the Si7005.

Conclusion

The development of new process technology has provided a highly-integrated device with temperature and humidity sensing, as well as heating elements controlled directly from the internal registers. This provides smaller, lower cost designs, but also means having to pay more attention to the manufacturing and long term stability of the system.

声明:本文内容及配图由入驻作者撰写或者入驻合作网站授权转载。文章观点仅代表作者本人,不代表电子发烧友网立场。文章及其配图仅供工程师学习之用,如有内容侵权或者其他违规问题,请联系本站处理。

举报投诉

发布评论请先 登录

相关推荐

热点推荐

温湿度传感器HTU31D在温湿度控器中的应用优势

温湿度控制器是一种用于监测和调节环境温度与湿度的设备,广泛应用于农业、仓储、工业生产、家庭等多个领域。其主要功能是维持特定环境条件,以确保产品质量和舒适的居住环境。 温湿度控制器的工作

IGBT模块工作环境温湿度条件解析

在散热器上安装的IGBT模块并非密封设计,尽管芯片上方有一层硅胶,但是水汽仍然可以通过外壳间隙以及硅胶进入器件芯片内部。因此,器件在使用和存储过程中,必须避免湿气或者腐蚀性气体。目前大

【案例1.6】在电子产品测试中与湿度有关的问题

【案例1.6】在电子产品测试中与湿度有关的问题本案例讨论与湿度有关的测试项目。【讨论】ESD(ElectronicStateDischarge,静电放电)敏感度测试是EMC测试中的一个重要测试项目

高精度温湿度传感器HDC302x系列技术解析与应用指南

Texas Instruments HDC302x/HDC302x-Q1数字湿度传感器是集成的电容式相对湿度 (RH) 和温度传感器。它采用紧凑的2.5mm x× 2.5mm封装,

E-GaN电源芯片U8733L集成外置温度检测和恒功率功能

E-GaN电源芯片U8733L集成外置温度检测和恒功率功能Yinlianbao开关电源NTC传感器能够感知微小的温度变化,一旦温度超过预设的

沐渥氮气柜控制面板湿度与温度报警功能详述

氮气柜控制面板的湿度与温度报警功能主要用于确保柜内环境稳定,防止敏感物料因环境波动而受损。低湿报警功能:当柜内湿度低于设定下限时触发报警。某些物料需要维持最低湿度,

红外感应技术的工作原理

红外感应技术是一种利用红外辐射进行物体检测和测量的技术。在自然界中,所有物体都会发出红外辐射,这种辐射的强度和波长分布取决于物体的温度和材料特性。红外感应技术通过感知和分析这些红外辐射

发表于 02-17 18:26

湿度大揭秘!如何影响功率半导体器件芯片焊料热阻?

近年来,随着电力电子技术的快速发展,功率半导体器件在风力发电、光伏发电、电动汽车等户外工况中的应用日益广泛。然而,这些户外环境往往伴随着较高的湿度,这对功率半导体器件的运行可靠性构成了严峻挑战

温度计使用注意事项 温度计与湿度计的区别

一、温度计使用注意事项 温度计是一种用于测量物体温度的仪器,广泛应用于日常生活、工业生产、科学研究等领域。在使用温度计时,为了确保测量结果的

雷达感应方案在照明行业的应用

雷达模组在智慧照明行业中的应用主要体现在人体感应控制和节能方面。利用电磁波探测目标,通过发射电磁波对目标进行照射并接收其回波,获得目标至电磁波发射点的距离、距离变化率(径向速度)、方位、角度等信息

HDC1080不能够测量温度和湿度是什么原因呢?

开始使用HDC1080 大概20片,一开始20片都能够正常测量温度和湿度,大概过了有1周时间后发现有2片HDC1080完全不能够测量温度和湿度,1片只能测试

发表于 12-18 07:27

在芯片上集成温度和湿度感应

在芯片上集成温度和湿度感应

评论