利用经验规律来寻找形成固溶体合金早已成为材料设计的重要步骤。但是,现有的经验规律预测的准确率很低,尤其是在诸如高熵合金等元素种类较多的情况下。

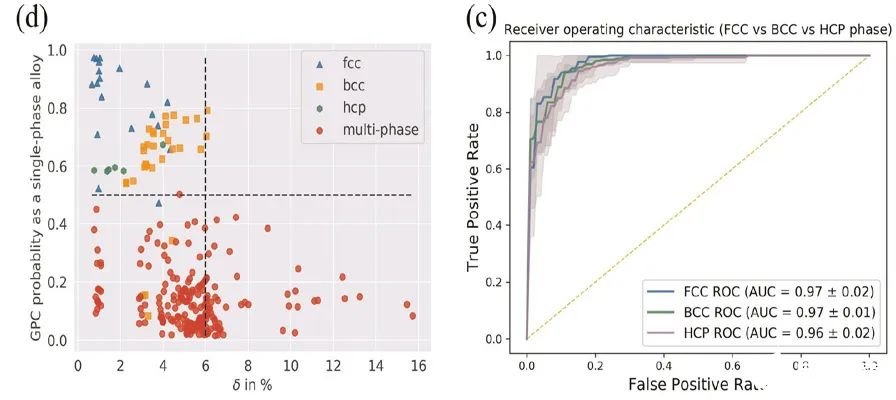

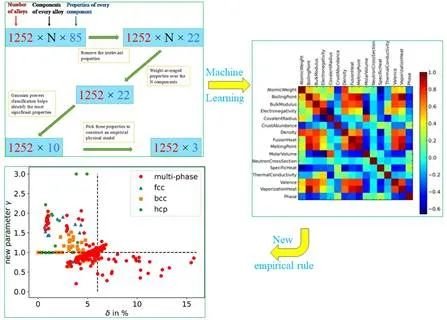

来自美国能源部两个国家实验室(NETL&ORNL)的研究团队(Zongrui Pei, Junqi Yin, Michael C. Gao, etc),通过机器学习获得的积极结果认识到:用经验规律预测合金固溶体这条路其实是可以很准确的,而之前的经验规律的局限性在于,没有选取到最重要的物理量作为参数。作者利用机器学习提供的物理量,构建了新的经验规律,并用其预测了三组高熵固溶体的形成,分别对应于最具代表性的晶体结构(FCC、BCC、HCP),得到了跟计算相图高度一致的结果。新的经验规律应用于高熵合金固溶体形成的预测,将非常直观而高效。

该文近期发表于npj Computational Materials 6: 50 (2020),英文标题与摘要如下。

Machine-learning informed prediction of high-entropy solid solution formation: Beyond the Hume-Rothery rules

Zongrui Pei,JunqiYin,Jeffrey A. Hawk, David E. Alman&Michael C. Gao, npj

The empirical rules for the prediction of solid solution formation proposed so far in the literature usually have very compromised predictability. Some rules with seemingly good predictability were, however, tested using small data sets. Based on an unprecedented large dataset containing 1252 multicomponent alloys, machine-learning methods showed that the formation of solid solutions can be very accurately predicted (93%)。 The machine-learning results help identify the most important features, such as molar volume, bulk modulus, and melting temperature. As such a new thermodynamics-based rule was developed to predict solid–solution alloys. The new rule is nonetheless slightly less accurate (73%) but has roots in the physical nature of the problem. The new rule is employed to predict solid solutions existing in the three blocks, each of which consists of 9 elements. The predictions encompass face-centered cubic (FCC), body-centered cubic (BCC), and hexagonal closest packed (HCP) structures in a high throughput manner. The validity of the prediction is further confirmed by CALculations of PHAse Diagram (CALPHAD) calculations with high consistency (94%)。 Since the new thermodynamics-based rule employs only elemental properties, applicability in screening for solid solution high-entropy alloys is straightforward and efficient.

责任编辑:pj

-

美国

+关注

关注

1文章

395浏览量

26794

发布评论请先 登录

半导体中的合金制备技术详解

如何保证合金电阻的稳定性与精度?

贴片电阻和合金电阻的差别

电阻焊技术在汽车铝合金焊接中的电子应用研究

激光焊接技术在焊接钼铜合金的工艺探究

Phase Lab铝基数据库,赋能7xxx系铝合金开发设计

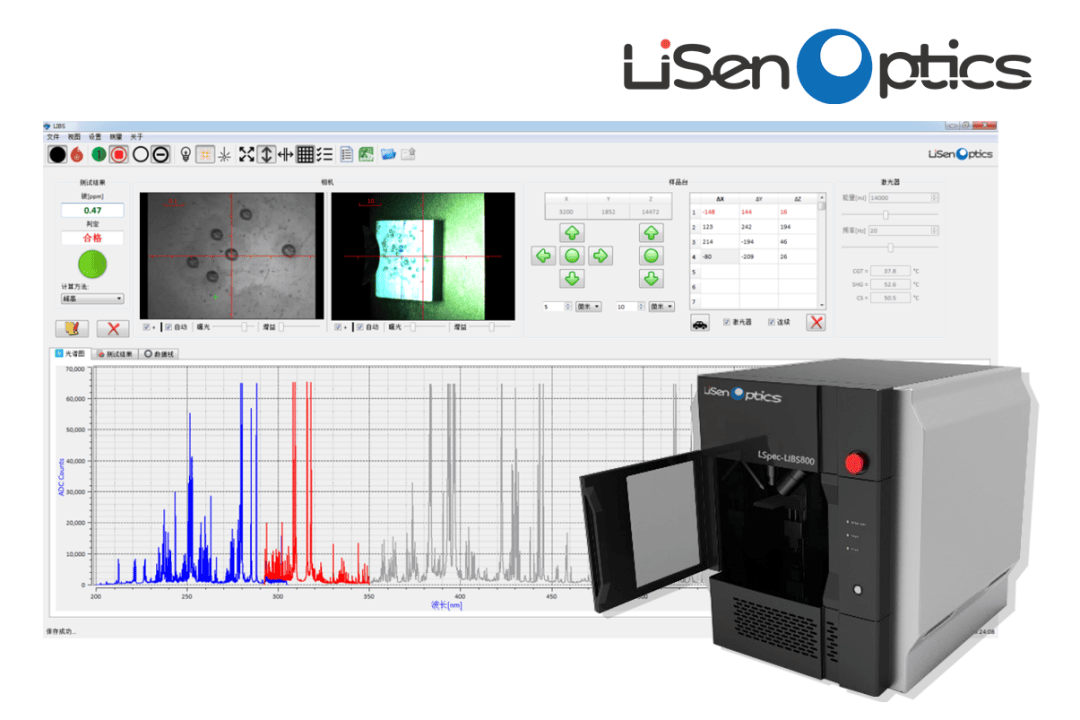

如何通过LIBS实现对合金材料的快速检测?

热电偶的材料及其影响

超导材料的制造工艺 超导材料的分类与比较

激光焊接技术在焊接钽金属的工艺应用

寻找形成固溶体合金成为材料设计的重要步骤

寻找形成固溶体合金成为材料设计的重要步骤

评论