资料介绍

描述

1.在Arduino IDE中安装库文件和板卡支持

为 Arduino IDE 添加“WIZnet WizFi360-EVB-PICO”支持

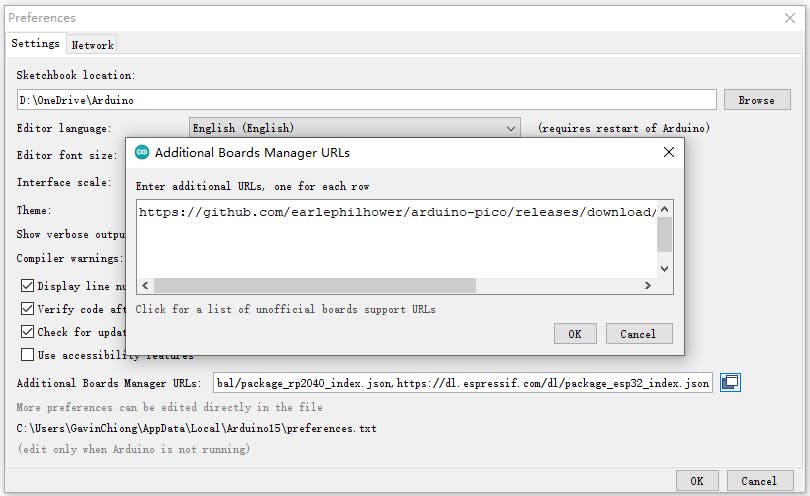

打开 Arduino IDE 并转到“文件”->“首选项”。

在弹出的对话框中,在“Additional Boards Manager URLs”字段中输入以下 URL:

https://github.com/earlephilhower/arduino-pico/releases/download/global/package_rp2040_index.json

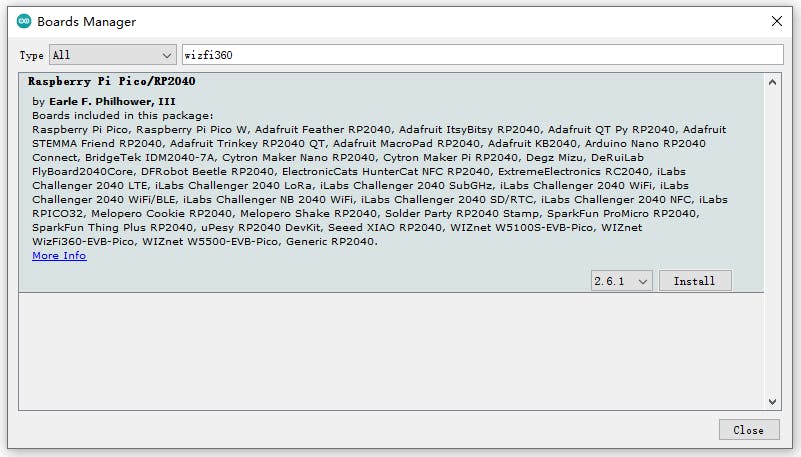

通过“Board Manager”搜索“WizFi360”并安装 Board 支持

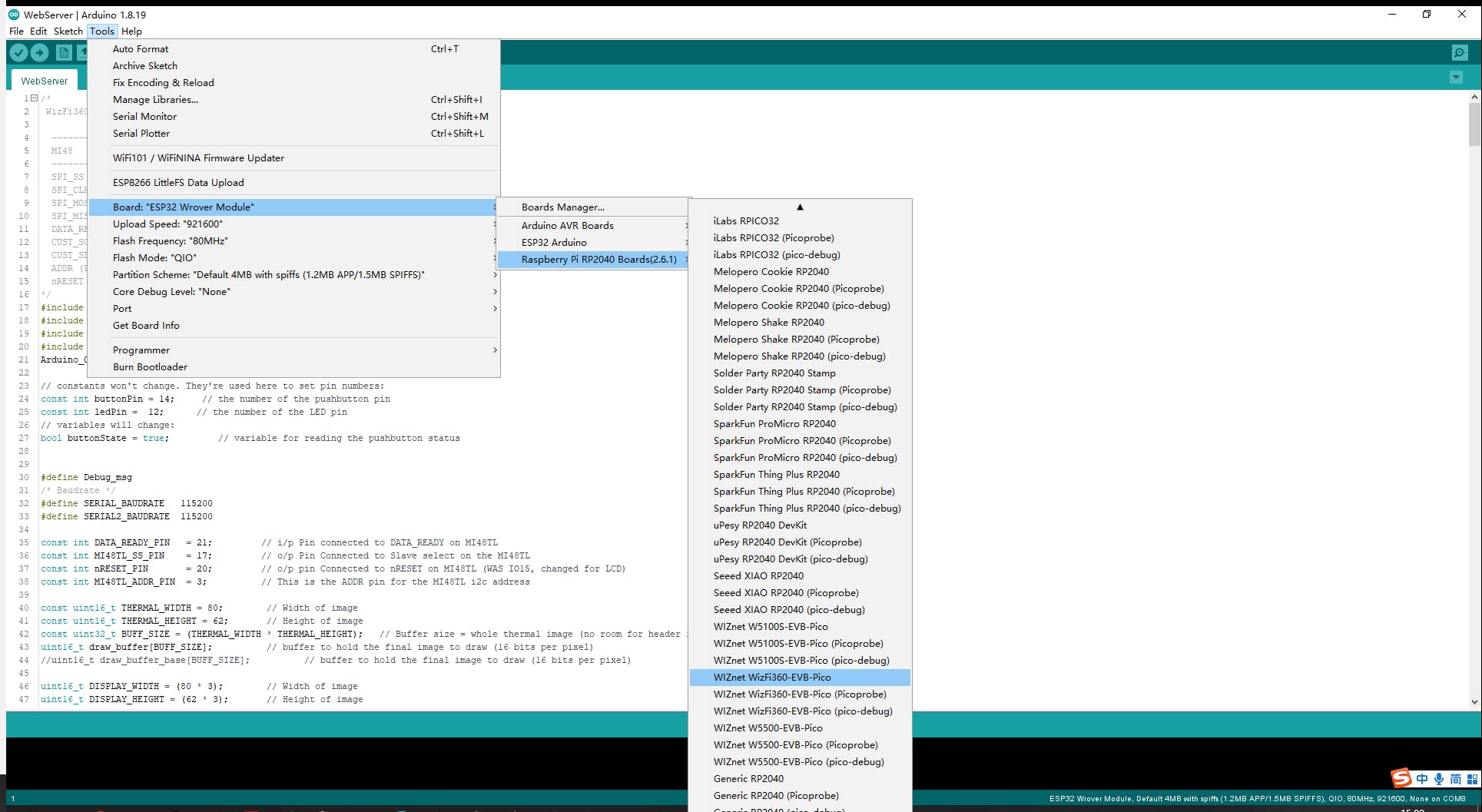

“工具->开发板:”***”-> Raspberry Pi RP2040 Boards(2.6.1)”选择“WIZnet WizFi360-EVB-PICO”。

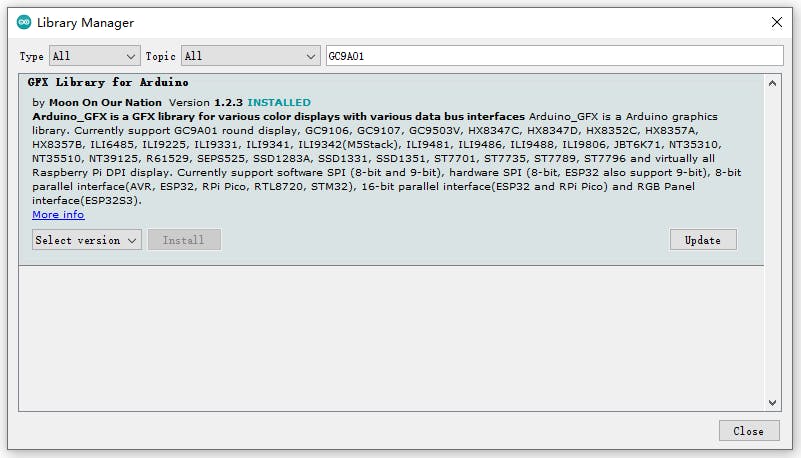

添加“GFX Library for rduino”,该库支持圆屏GC9A01。

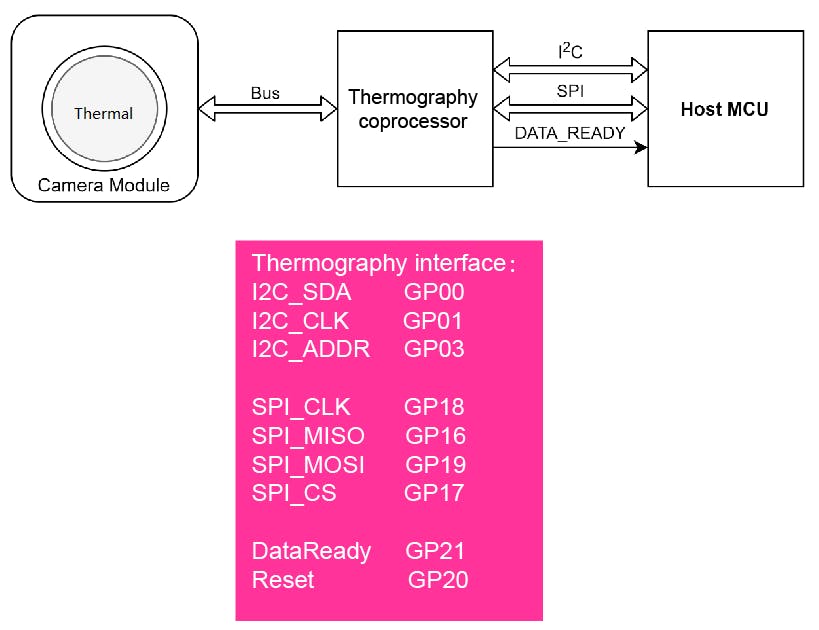

2. Thermography Carmera和协处理器初始化和数据处理

热成像相机和协处理器接口和功能引脚初始化

#include // i2c library (standard Arduino library)

#include // SPI library (standard Arduino library)

const int THERMAL_DATA_READY_PIN = 21; //Pin connected to DATA_READY

const int THERMAL_CS_PIN = 17; //Pin Connected to CS

const int THERMAL_nRESET_PIN = 20; //pin Connected to nRESET

const int THERMAL_ADDR_PIN = 3; //The Thermography i2c address

uint16_t THERMAL_Addr = 0x40;

/*i2c address for Thermography (0x40 if Thermography_ADDR_PIN =0 or 0x41 if Thermography_ADDR_PIN = 1 )*/

热像注册地址

// Now the addresses for each of the registers within the device

const uint16_t THERMAL_FRAME_MODE = 0xB1; // Frame Mode register address

const uint16_t THERMAL_SW_VERSION = 0xB2; // swVersion register address

const uint16_t THERMAL_BUILD = 0xB3; // swVersion build register address

const uint16_t THERMAL_FRAME_RATE = 0xB4; // Frame Rate register addres

const uint16_t THERMAL_POWER_DOWN = 0xB5; // Power down register address

const uint16_t THERMAL_STATUS_ERROR = 0xB6; // Status Error register address

const uint16_t THERMAL_SENSOR_TYPE = 0xBA; // SenXor type register address

const uint16_t THERMAL_EMISSIVITY = 0xCA; // emissivity register address

const uint16_t THERMAL_FILTER_CONTROL = 0xD0; // filter control (bits 0-2 R_W)

const uint16_t THERMAL_FILTER_SETTINGS_LSB = 0xD1; // filter setting LSB (0x32 default, 0x80 rec)

const uint16_t THERMAL_FILTER_SETTINGS_MSB = 0xD2; // filter setting MSB (0x00 default)

const uint16_t THERMAL_ROLLING_AVG_SETTING = 0xD3; // rolling average setting (0x04 default)

I2C读写Thermography寄存器地址

// =========================================================================

// Function to write i2c register

// =========================================================================

void WriteI2c(int RegAddr, unsigned char RegData)

{

Wire.beginTransmission(Addr); // Begin transmission to the Sensor

Wire.write (RegAddr); // Set the address for the requested register

Wire.write (RegData); // Write the data for that register

Wire.endTransmission(true); // Release i2c bus - so others can use it (can have multiple slaves & masters connected

return;

}

// =========================================================================

// Function to read i2c register

// =========================================================================

unsigned char ReadI2c(int RegAddr)

{

unsigned char Result;

Wire.beginTransmission(Addr); // Begin transmission to the Sensor

Wire.write (RegAddr); // Set the address for the requested register

Wire.endTransmission(); // End tranmission We should have set the address of the register

Wire.requestFrom(Addr, 1); // Tell slave we need to read 1 byte from the current register

Result = Wire.read(); // read that Serial Number byte (register will auto increment)

Wire.endTransmission(true); // Release i2c bus - so others can use it

return Result;

}

在“void setup()”中通过I2C BUS获取和设置参数

THERMAL_FILTER_CONTROL :将此位设置为 1 指示在连续捕获模式下运行,从而连续从相机模块获取数据并更新可通过 SPI 接口访问的读出缓冲区。将此位重置为 0 指示停止连续数据采集。这也会将 DATA_READY 引脚和 STATUS 寄存器的相应位 4 重置为 0。

THERMAL_FRAME_RATE :这些位的值确定主机控制器可以通过 SPI 接口从输出帧缓冲区读取热数据帧的速率。该值必须是一个无符号整数,表示所连接相机模块的最大帧速率 FPS_MAX 的帧速率除数:FPS = FPS_MAX / FRAME_RATE_DIVIDER。例外情况是 FRAME_RATE = 0,这会产生 FPS_MAX = 24FPS。

THERMAL_FRAME_MODE :将此位设置为 1 会消除通过 SPI 接口传输的热数据帧中的标头。将此位重置为 0 包括热数据帧中的 HEADER,

Wire.begin(); // Initialise and configure the i2C//

Wire.setClock(400000); // use 400 kHz I2C//

pinMode(THERMAL_DATA_READY_PIN, INPUT_PULLUP);

pinMode (nRESET_PIN, OUTPUT);

digitalWrite (nRESET_PIN, LOW); // First put the THERMAL in reset - THIS NEEDS TO BE TIMED//

pinMode (THERMAL_ADDR_PIN, OUTPUT);

digitalWrite (THERMAL_ADDR_PIN, LOW); // Set the THERMAL i2c addrees LOW = 0x40 HIGH = 0x41//

pinMode(THERMAL_CS_PIN, OUTPUT); // Configure CS pin for THERMAL

digitalWrite (THERMAL_CS_PIN, HIGH);

delay(200); // Wait 0.2 seconds //

digitalWrite (nRESET_PIN, HIGH); // remove reset to the THERMAL - allow it to boot//

delay(1000); // Wait 1 seconds for the THERMAL to boot

SPI.begin(); // Initialise the SPI

// =========================================================================

// Read all the individual i2c registers

// Uses ReadI2c() routine

// =========================================================================

frameMode = ReadI2c(THERMAL_FRAME_MODE);

swVersion = ReadI2c(THERMAL_SW_VERSION);

build = ReadI2c(THERMAL_BUILD);

frameRate = ReadI2c(THERMAL_FRAME_RATE);

powerDown = ReadI2c(THERMAL_POWER_DOWN);

statusError = ReadI2c(THERMAL_STATUS_ERROR);

senxorType = ReadI2c(THERMAL_SENSOR_TYPE);

emissivity = ReadI2c(THERMAL_EMISSIVITY);

// =========================================================================

// Write any registers required beofre starting exitig setup

// and starting Data aquisition

// =========================================================================

WriteI2c(THERMAL_FILTER_SETTINGS_LSB, 0x80);

WriteI2c(THERMAL_FILTER_SETTINGS_MSB, 0x00);

WriteI2c(THERMAL_FILTER_CONTROL, 0x02);

delay(100); // currently required after modifying filter values//

WriteI2c(THERMAL_FRAME_RATE, 0x3); // Write the Frame_rate register 0x1 = as fast as possible (24FPS)//

WriteI2c(THERMAL_FRAME_MODE, 0x3); // Write the Frame_mode register 0x3 = capture continuous with header)//

在“void loop()”中通过SPI BUS获取camera Header和data

SPI 时钟设置为 40MHz,来自传感器的数据相对于屏幕翻转,因此我们必须向后绘制行。

void Get_sensor_data()

{

dataReady = digitalRead(THERMAL_DATA_READY_PIN);

// Read the state on THERMAL_DATA_READY_PIN line

if ( digitalRead (THERMAL_DATA_READY_PIN) == HIGH) {

// Wait for THERMAL_DATA_READY_PIN to assert

Serial.println ("Data ready!!");

//THERMAL_DATA_READY_PIN has been asserted so data is now available on SPI bus

SPI.beginTransaction(SPISettings(40000000, MSBFIRST, SPI_MODE0));

digitalWrite (THERMAL_CS_PIN, LOW);

for (int i = 0; i < THERMAL_WIDTH; i++)

{

header_buffer[i] = SPI.transfer16(0x0);

// write data to the header buffer

}

for (int j = 0; j < THERMAL_HEIGHT; j++)

{

for (int i = 0; i < THERMAL_WIDTH; i++)

{

THERMAL_SpiData = SPI.transfer16(0x0);

// The data from the sensor is flipped with respect to the screen so we have to draw the rows backwards

draw_buffer[((THERMAL_WIDTH - 1) - i) + (j * THERMAL_WIDTH)] = THERMAL_SpiData;

} // (finished a row)

}

// We have now read the entire frame of data

digitalWrite (THERMAL_CS_PIN, HIGH);

SPI.endTransaction();

}

}

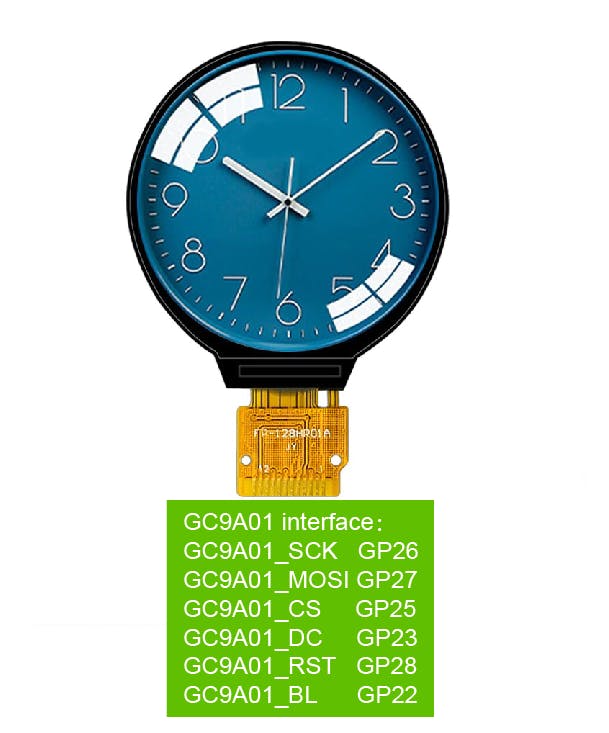

3. 在屏幕上显示热数据(GC9A01)。

#include

Arduino_GFX *tft = create_default_Arduino_GFX();

在“libraries\GFX_Library_for_Arduino\src\Arduino_GFX_Library.h”中定义 GC9A01 使用的引脚

#elif defined(ARDUINO_RASPBERRY_PI_PICO)||defined(ARDUINO_WIZNET_WIZFI360_EVB_PICO)||defined(ARDUINO_WIZNET_5100S_EVB_PICO)

#define DF_GFX_SCK 26

#define DF_GFX_MOSI 27

#define DF_GFX_MISO GFX_NOT_DEFINED

#define DF_GFX_CS 25

#define DF_GFX_DC 23

#define DF_GFX_RST 28

#define DF_GFX_BL 22

在“void setup()”中初始化屏幕并打开屏幕的背光

tft->begin();

tft->fillScreen(BLACK);

pinMode(22, OUTPUT);

digitalWrite(22, HIGH);

Display_Begin();

将热数据的每一个像素点转化为颜色(RGB565),通过根据minmax中温度值的相对位置(thermal Header中识别范围内的温度差)在colormap中找到对应的颜色信息。

通过“DISPLAY_buffer”函数显示所有温度颜色信息。由于摄像头分辨率只有80*62,而GC9A01的屏幕分辨率为240*240,所以每个温度点扩展为3*3显示。

// =========================================================================

// Colour conversion - one pixel at a time

// The draw_buffer starts as 16 bit sensor data

// At the end it is 16 bit RGB (5-6-5)

// =========================================================================

for (int j = 0; j < THERMAL_HEIGHT; j++) {

for (int i = 0; i < THERMAL_WIDTH; i++) {

pixelVal = draw_buffer[(i) + (j * THERMAL_WIDTH)];

if (pixelVal <= THERMAL_MinVal) {

lutIndex = 0;

}

else if (pixelVal >= THERMAL_MaxVal) {

lutIndex = 255;

}

else {

lutIndex = map (pixelVal, THERMAL_MinVal, THERMAL_MaxVal , 0, 0xff);

}

for(int m = 0; m<3; m++)

{

DISPLAY_buffer[(i*3)+m + (j*3) * DISPLAY_WIDTH]= palette[lutIndex];

DISPLAY_buffer[(i*3)+m + ((j*3)+1) * DISPLAY_WIDTH]= palette[lutIndex];

DISPLAY_buffer[(i*3)+m + ((j*3)+2) * DISPLAY_WIDTH]= palette[lutIndex];

}

}

}

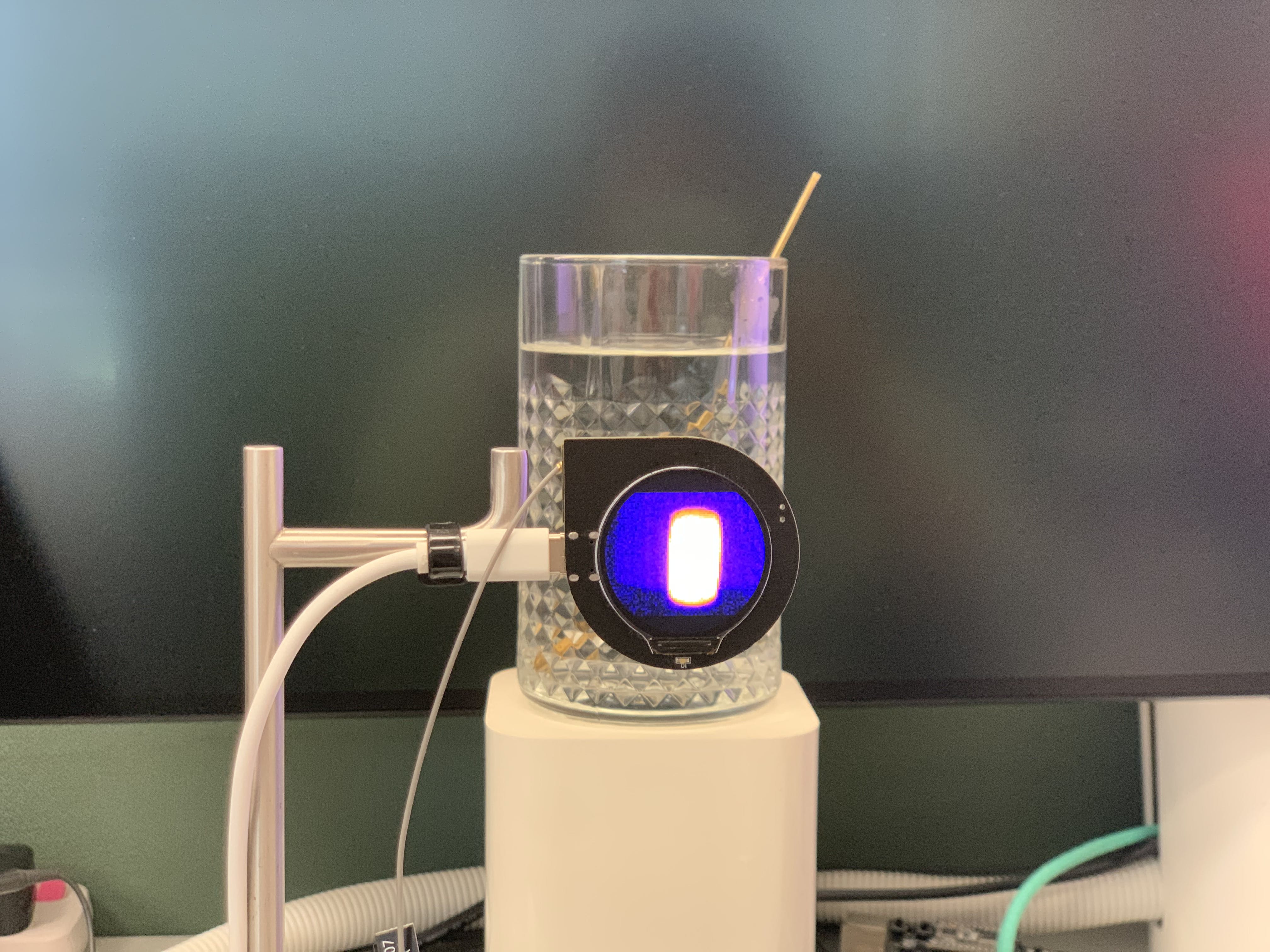

然后我们得到了这个项目中的第一张热水热成像图。

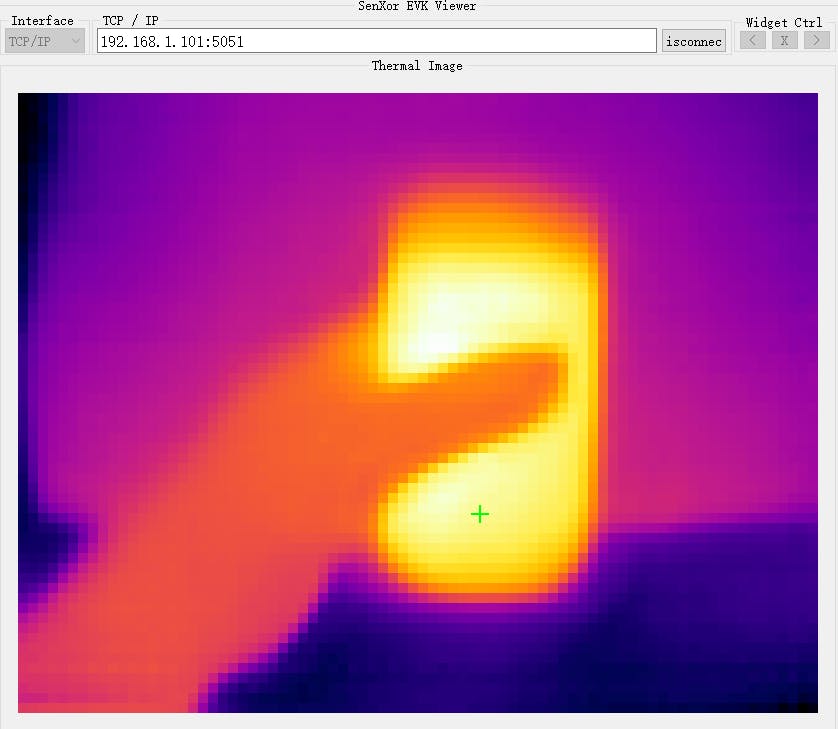

4. WizFi360通过WiFi与热查看器软件通信。

Thermal Viewer 软件作为 TCP 客户端使用端口 5051。

#include "WizFi360.h"

// Wi-Fi info //

char ssid[] = "WIZNET_test"; // your network SSID (name)//

char pass[] = "********"; // your network password//

int status = WL_IDLE_STATUS; // the Wifi radio's status//

WiFiServer server(5051);

初始化WizFi360模块的串口,修改波特率为2000000bps(wizfi360的最大波特率)。

第一次初始化为115200,然后在WiZfi360库的初始化部分加入设置波特率(2000000),第二次改为2000000bps。

// initialize serial port for WizFi360 module//

#if defined(ARDUINO_WIZNET_WIZFI360_EVB_PICO)

Serial2.begin(2000000);

WiFi.init(&Serial2);

Serial2.begin(2000000);

#endif

在“void setup()”中查看wifi的wizfi360 Link状态

// check for the presence of the shield//

if (WiFi.status() == WL_NO_SHIELD) {

Serial.println("WiFi shield not present");

// don't continue//

while (true);

}

// attempt to connect to WiFi network//

while ( status != WL_CONNECTED) {

Serial.print("Attempting to connect to WPA SSID: ");

Serial.println(ssid);

// Connect to WPA/WPA2 network//

status = WiFi.begin(ssid, pass);

}

Serial.println("You're connected to the network");

当热查看器软件连接到此服务器(WizFi360)时,RP2040 读取热数据“Get_sensor_data()”并将数据发布到 TCP 客户端(热查看器软件)。

先传热像头,再传热像素数据(80*62 16bits)。

WiFiClient client;

if (client) {

Serial.println("Connected");

socket_status = client.connected();

socket_status_cnt = 0;

delay(1000);

uint8_t i;

while (socket_status&&!buttonState)

{

switch(socket_send_status)

{

case 0:

{

Get_sensor_data();

socket_send_result = client.write((uint8_t*)header_buffer,160);

socket_send_status = 1;

}break;

case 1:

{

if(socket_send_result == 160 ){

socket_sendnum = 9920; //80*62*2//

socket_send_status = 2;

i=0;

}else if(socket_send_result == 0){

socket_send_status = 4;

}

}break;

case 2:

{

if(socket_sendnum >=2048)

{

socket_send_result = client.write((uint8_t*)(draw_buffer+(i*1024)),2048);

}

else

{

socket_send_result = client.write((uint8_t*)(draw_buffer+(i*1024)),socket_sendnum);

}

socket_send_status = 3;

}break;

case 3:

{

if(socket_sendnum >= 2048)

{

if(socket_send_result == 2048)

{

socket_sendnum -= 2048;

i++;

socket_send_status = 2;

}else if(socket_send_result == 0){

socket_send_status = 4;

}

}

else

{

if(socket_send_result == socket_sendnum)

{

socket_sendnum = 0;

socket_send_status = 4;

}

}

}break;

case 4:

{

socket_status_cnt ++;

if(socket_status_cnt == 20)

{

socket_status = client.connected();

if(socket_status == 0)

{

client.stop();

}

socket_status_cnt = 0;

}

socket_send_status = 0;

}break;

}

}

}

Thermal viewer 软件接收像素数据,它可以显示和显示这些像素的最高温度。

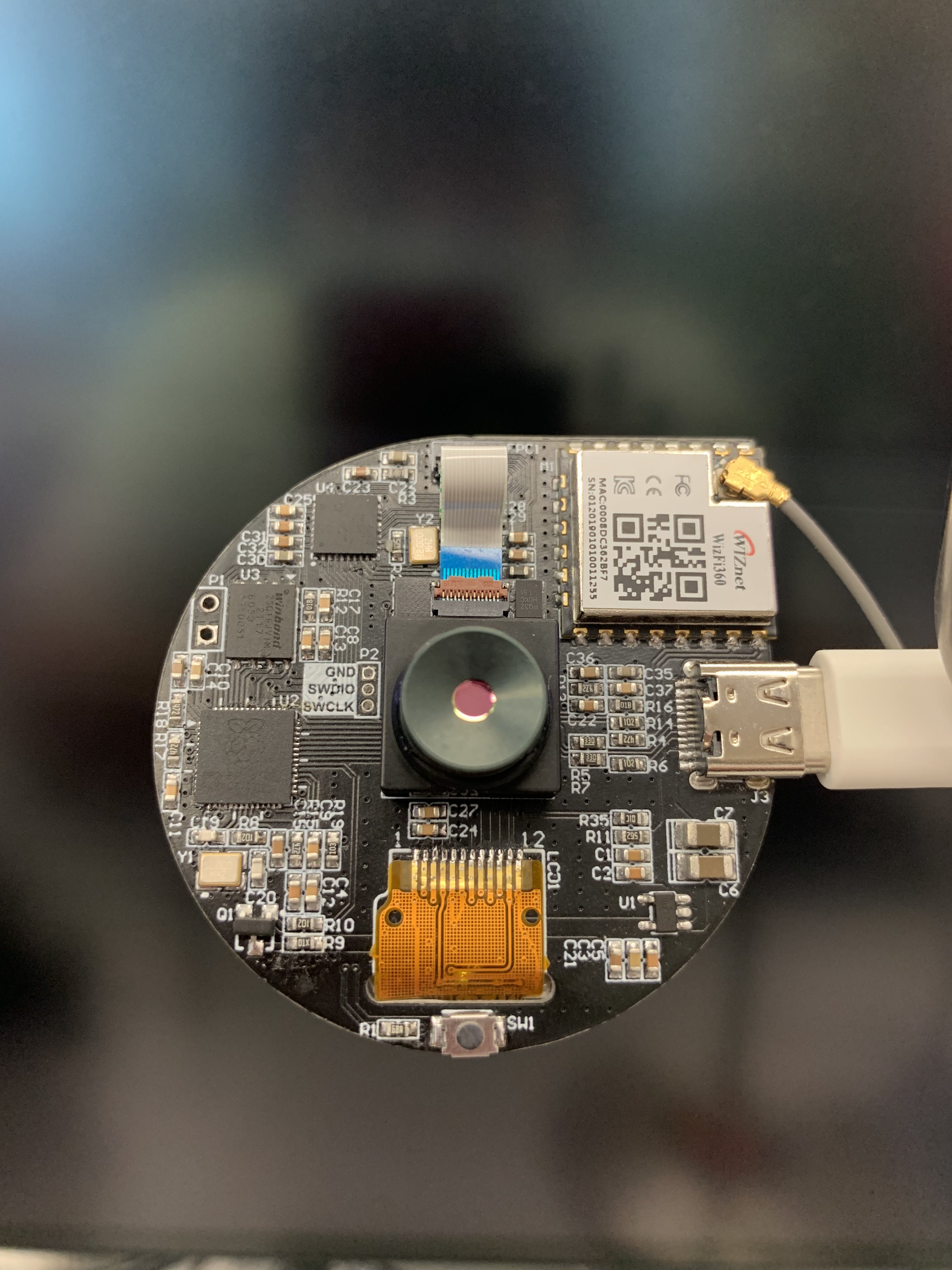

硬件如下图

结束。

注意:由于签署了保密协议,一些细节不能公开。

- 远程编程Raspberry Pi Pico 0次下载

- Raspberry Pi Pico上的ADC采样和FFT 4次下载

- Raspberry Pi Pico多功能入门套件 0次下载

- 将Arduino库与Raspberry Pi Pico C/C++ SDK一起使用 0次下载

- 使用Wiznet Pico WizFi360和WS2812B LED制成的RGB天气灯 0次下载

- 将WizFi360 EVB Pico连接到Azure IoT Cloud 0次下载

- WizFi360 EVB Mini脉搏血氧仪开源 1次下载

- Raspberry Pi Pico作为HID鼠标 1次下载

- 基于树莓派Raspberry Pi Pico的自动浇花系统 5次下载

- 如何将WizFi360 EVB Mini添加到树莓派Pico Python 0次下载

- 使用Raspberry Pi Pico的LED序列 0次下载

- Raspberry Pi Pico:使用PIO驱动伺服 0次下载

- Grove UART WizFi360串行收发模块 0次下载

- 适用于Raspberry Pi 4的Raspberry Pi Pico开发板 6次下载

- raspberry pi Pico使用MicroPython变砖后的解决方法 2次下载

- 5分钟内将Raspberry Pi Pico变成简单的示波器+波形发生器 453次阅读

- 基于Raspberry Pi 5的蜂窝物联网项目 646次阅读

- 红外热成像仪的基础知识 868次阅读

- 使用Raspberry Pi Pico W和MicroPython开发物联网应用 939次阅读

- Pico W的无线功能 596次阅读

- 用于测试项目的4个最佳树莓派Raspberry Pi模拟器 4868次阅读

- DIY小熊派红外热成像仪 2057次阅读

- 基于Raspberry Pi Pico的云端温湿度监测站设计 1565次阅读

- 基于树莓派产品 Raspberry Pi微控制器板的优缺点 2389次阅读

- 如何从Raspberry Pi Pico的模数转换器捕获数据计算? 2340次阅读

- 基于Raspberry Pi Pico开发先进的家庭自动化系统 2630次阅读

- 基于在Raspberry Pi Zero W的基础上实现设计微型机器人 1914次阅读

- 微雪电子ZeroW| Raspberry Pi ZeroW主板简介 2202次阅读

- 微雪电子Raspberry Pi 3 Model主板简介 2118次阅读

- 一文了解Raspberry Pi 4各项性能跑分 2.8w次阅读

下载排行

本周

- 1山景DSP芯片AP8248A2数据手册

- 1.06 MB | 532次下载 | 免费

- 2RK3399完整板原理图(支持平板,盒子VR)

- 3.28 MB | 339次下载 | 免费

- 3TC358743XBG评估板参考手册

- 1.36 MB | 330次下载 | 免费

- 4DFM软件使用教程

- 0.84 MB | 295次下载 | 免费

- 5元宇宙深度解析—未来的未来-风口还是泡沫

- 6.40 MB | 227次下载 | 免费

- 6迪文DGUS开发指南

- 31.67 MB | 194次下载 | 免费

- 7元宇宙底层硬件系列报告

- 13.42 MB | 182次下载 | 免费

- 8FP5207XR-G1中文应用手册

- 1.09 MB | 178次下载 | 免费

本月

- 1OrCAD10.5下载OrCAD10.5中文版软件

- 0.00 MB | 234315次下载 | 免费

- 2555集成电路应用800例(新编版)

- 0.00 MB | 33566次下载 | 免费

- 3接口电路图大全

- 未知 | 30323次下载 | 免费

- 4开关电源设计实例指南

- 未知 | 21549次下载 | 免费

- 5电气工程师手册免费下载(新编第二版pdf电子书)

- 0.00 MB | 15349次下载 | 免费

- 6数字电路基础pdf(下载)

- 未知 | 13750次下载 | 免费

- 7电子制作实例集锦 下载

- 未知 | 8113次下载 | 免费

- 8《LED驱动电路设计》 温德尔著

- 0.00 MB | 6656次下载 | 免费

总榜

- 1matlab软件下载入口

- 未知 | 935054次下载 | 免费

- 2protel99se软件下载(可英文版转中文版)

- 78.1 MB | 537798次下载 | 免费

- 3MATLAB 7.1 下载 (含软件介绍)

- 未知 | 420027次下载 | 免费

- 4OrCAD10.5下载OrCAD10.5中文版软件

- 0.00 MB | 234315次下载 | 免费

- 5Altium DXP2002下载入口

- 未知 | 233046次下载 | 免费

- 6电路仿真软件multisim 10.0免费下载

- 340992 | 191187次下载 | 免费

- 7十天学会AVR单片机与C语言视频教程 下载

- 158M | 183279次下载 | 免费

- 8proe5.0野火版下载(中文版免费下载)

- 未知 | 138040次下载 | 免费

电子发烧友App

电子发烧友App

创作

创作 发文章

发文章 发帖

发帖  提问

提问  发资料

发资料 发视频

发视频 上传资料赚积分

上传资料赚积分

评论