1.Introduction

This document indicates the hardware/software design notes to migrate from Beckhoff ET1100 ESC solution to AX58100 ESC solution.

2.FunctionsOverview

The AX58100 is a 2/3-port EtherCAT Slave Controller (ESC), licensed from Beckhoff Automation, with two integrated Fast Ethernet PHYs which support 100Mbps full-duplex operation and HP Auto-MDIX. AX58100 supports 9 Kbytes Process Data RAM, 8 Fieldbus Memory Management Units (FMMUs), 8 Sync-Managers and a 64-bit Distributed Clock.

Compared to other EtherCAT slave controller solutions, the AX58100 integrates two embedded Fast Ethernet PHYs which can support both copper and fiber industrial Ethernet applications and supports some additional interfaces such as Pulse Width Modulation (PWM), Incremental (ABZ)/Hall Encoder, SPI master, 32 Digital I/O, Emergency Stop Input, etc. for designers to easily implement AX58100 on different EtherCAT industrial fieldbus applications without extra microprocessor. The AX58100 provides SPI slave and Local bus Process Data Interfaces (PDI) to provide an easy way for system designers to implement the standard EtherCAT communication functionalities on those traditional non-EtherCAT MCU and DSP industrial platforms.

The AX58100 provides a cost-effective EtherCAT slave controller solution for industrial automation, motion/motor/Digital IO control, Digital to Analog (DAC)/Analog to Digital (ADC) converters control, sensors data acquisition, robotics, etc. industrial Ethernet fieldbus applications.

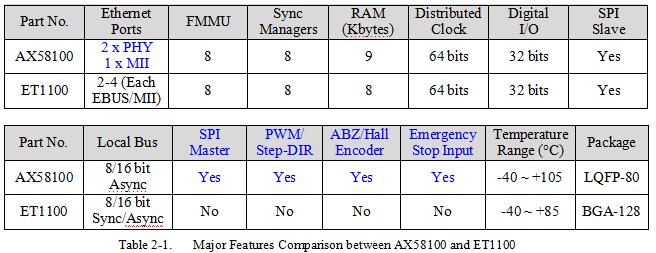

The following is the major features comparison between AX58100 and Beckhoff ET1100 ESC solutions.

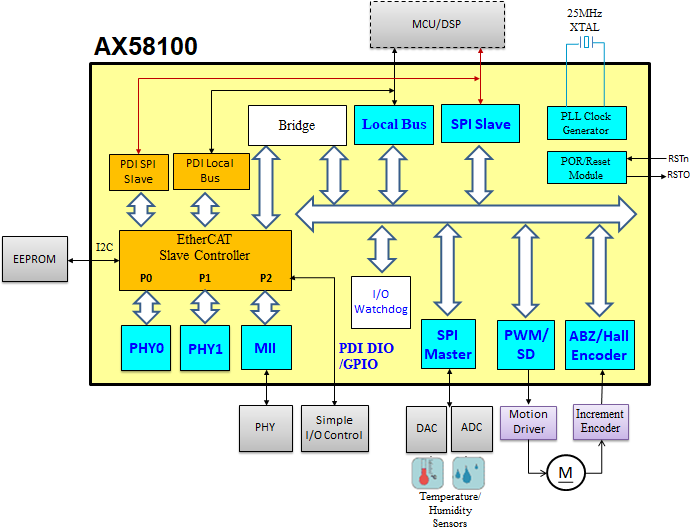

2-1. BlockDiagram

The following are the block diagrams of AX58100 and ET1100.

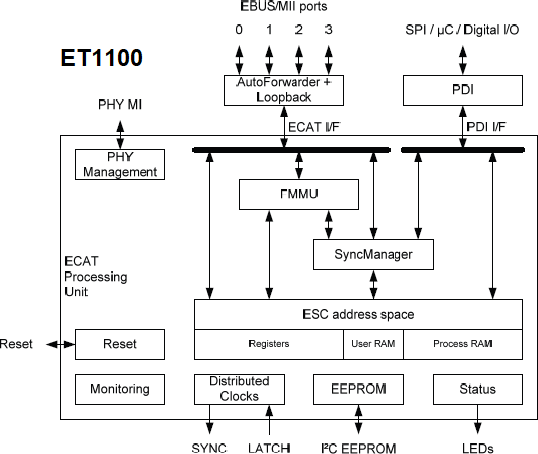

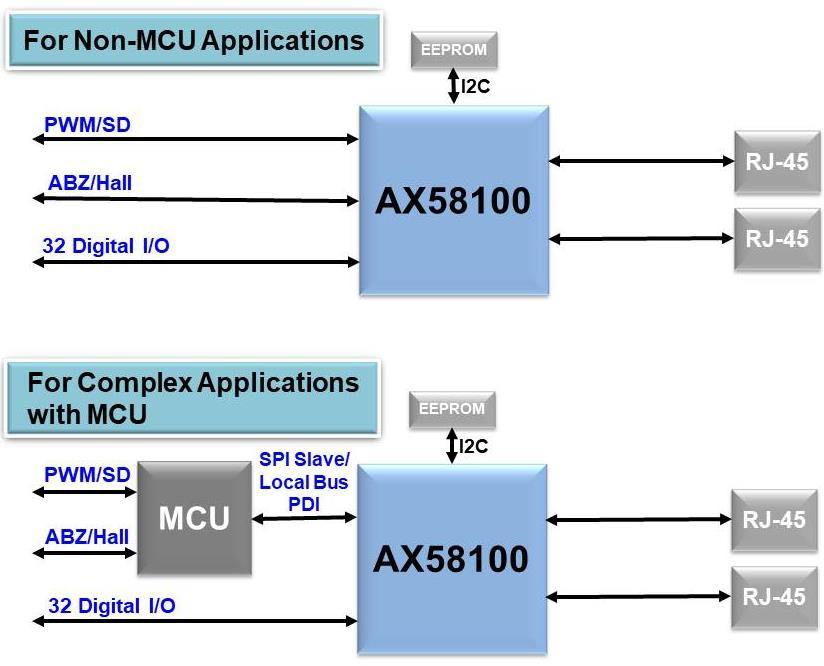

2-2. ApplicationDiagram

The following are the typical applications diagrams of AX58100 and ET1100. The AX58100 integrates additional interfaces such as Pulse Width Modulation (PWM), ABZ/Hall Encoder, SPI master, 32 Digital I/O, Emergency Stop Input, etc. for designers to easily implement AX58100 on different EtherCAT industrial fieldbus applications without extra microprocessor.

Figure2-3. AX58100 Application Diagram

Figure2-4. ET1100 Application Diagram

3.HardwareTransition

This section indicates the hardware design considerations while migrating from Beckhoff ET1100 ESC solution to AX58100 ESC solution.

3-1. Bootstrap Hardware ConfigurationPins

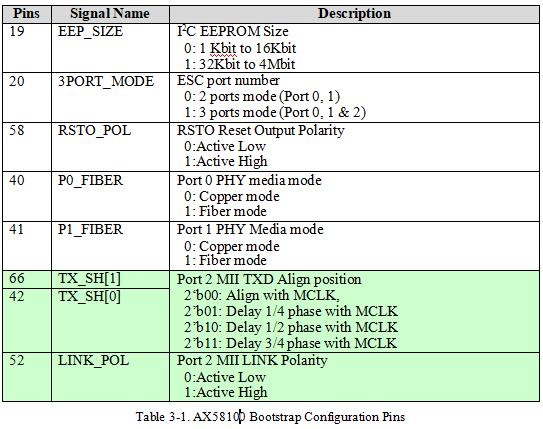

The AX58100 supports five multi-function bootstrap pins (pin 19, 20, 58, 40, and 41) for five hardware configurations, i.e. external I2C EEPROM size, ESC supported port number, RSTO polarity and integrated port 0/1 PHY media mode; and supports other three multi-function bootstrap pins (pin 42, 52, 66) for the configuration of port 2 MII signals. User needs to utilize an external resistor to pull up/down these bootstrap pins for correct AX58100 hardware configuration.

Beckhoff supports different hardware configuration pins based on the ET1100 product design specification. Please refer to Beckhoff ET1100 datasheet for details.

3-2. EthernetPorts

The AX58100 ESC, which is licensed from Beckhoff Automation, supports two embedded PHYs and an optional MII interface for flexible network topology. The embedded Fast Ethernet PHYs support 100Mbps full-duplex operation and HP Auto-MDIX, and are fully compliant with the 100BASE-TX and 100BASE-FX Ethernet standards such as IEEE 802.3u, and ANSI X3.263- 1995 (FDDI-TP-PMD) for both copper and fiber industrial Ethernet applications.

The optional MII interface of AX58100 ESC is optimized for low processing/forwarding delays by omitting a transmit FIFO. To allow this, the ESC has additional requirements to Ethernet PHY, which is easily accomplished by several PHY vendors. Please refer to Beckhoff’s PHY Selection Guide to select a proper Ethernet PHY.

AX58100 Port 0 and Port 1 integrate embedded Ethernet PHYs, and Port 2 is an optional MII interface which are multi-function pins shared with others interfaces (i.e. PWM, Hall, Local Bus, Digital I/O). Packets are forwarded in the following order:

Port 0 -> EtherCAT Processing Unit -> Port 1 -> Port 2

AX58100 supports six Bootstrap pins (pin 20, 40-42, 52 and 66) for Ethernet ports hardware configurations. Please refer to Table 3-1for details.

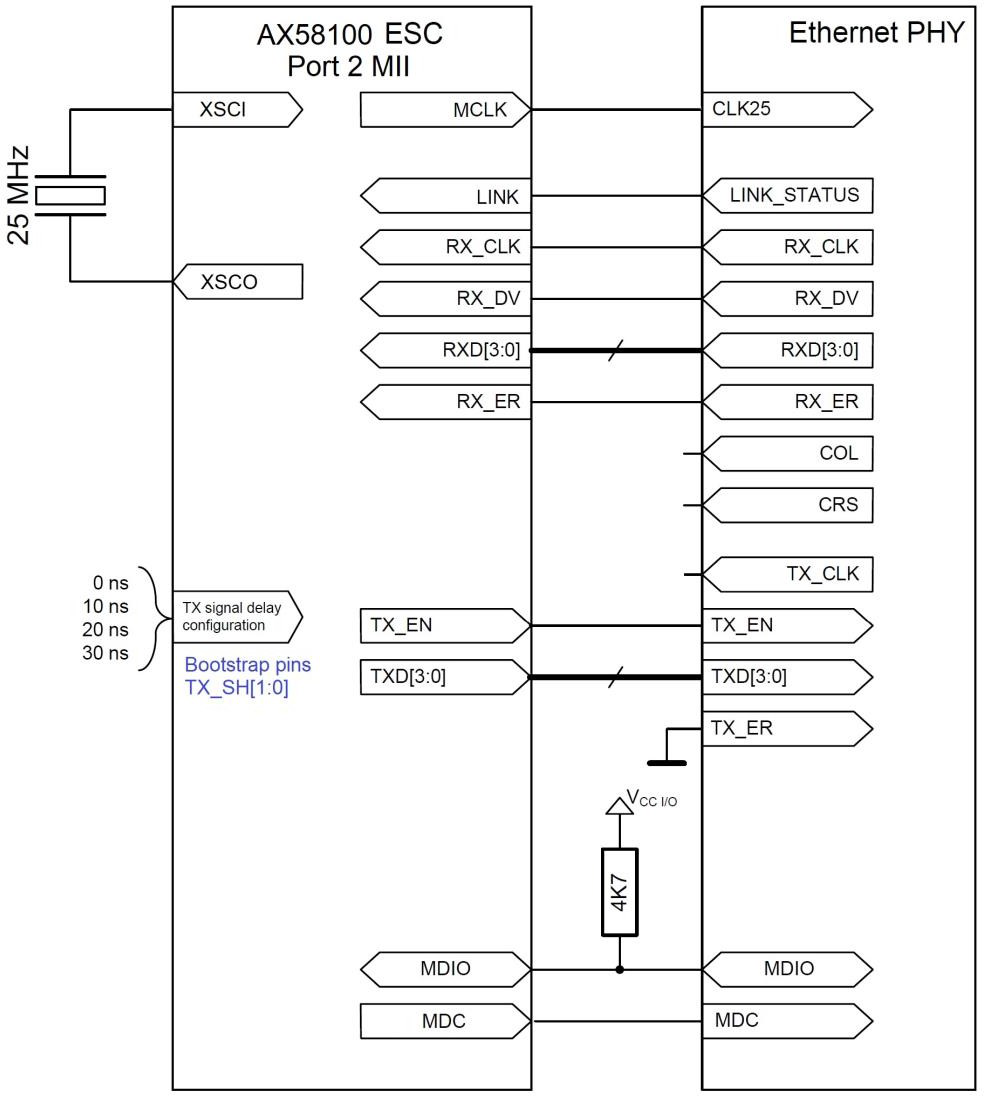

The following is the principle connection between AX58100 Port 2 MII interface and Ethernet PHY. The clock source of the Ethernet PHYs and ESC must be the same quartz. The TX_CLK is not connected because the ESCs do not incorporate a TX FIFO. The TX signals can be delayed inside the ESC by setting AX58100 TX_SH[1:0] bootstrap pins for TX_CLK phase shift compensation. The LINK is connected to the PHY LED output indicating a 100 Mbps (Full Duplex) link.

Figure3-1.The principle connection between AX58100 Port 2 MII interface and EthernetPHY

3-3.Digital I/O PDI

由于篇幅限制无法完整显示整篇文章,若需获取整份PDF文档,或其他相关AX58100资料,请发Mail至以下地址:info@chipreal.com

-

ASIX

+关注

关注

0文章

11浏览量

9251 -

ethercat

+关注

关注

17文章

441浏览量

37687 -

ax58100

+关注

关注

0文章

12浏览量

7612 -

ET1100

+关注

关注

0文章

1浏览量

2170

发布评论请先 登录

相关推荐

爱芯元智AX620E和AX650系列芯片正式通过PSA Certified安全认证

ax58100和lan9252区别

AD9233转换结果需要补偿一个偏置量吗?

选用AD7190转换器做数据采集仪表,在仪表附近用对讲机通话时数据就跳动很大的原因?

ADAS3022回读的前16位转换结果不对是什么原因导致的?

用两片AD7190转换4个压力传感器信号,四个通道数据有时会丢失一个通道数据的原因?

用AD7606转换的精度太差是什么原因造成的?

AD7606转换值不稳定的原因?

请问一下控制ad9233转换和停止转换是只能通过直接控制时钟通断来实现吗?

使用AD4696转换器,在有源滤波器之后是否还需要增加运放驱动?

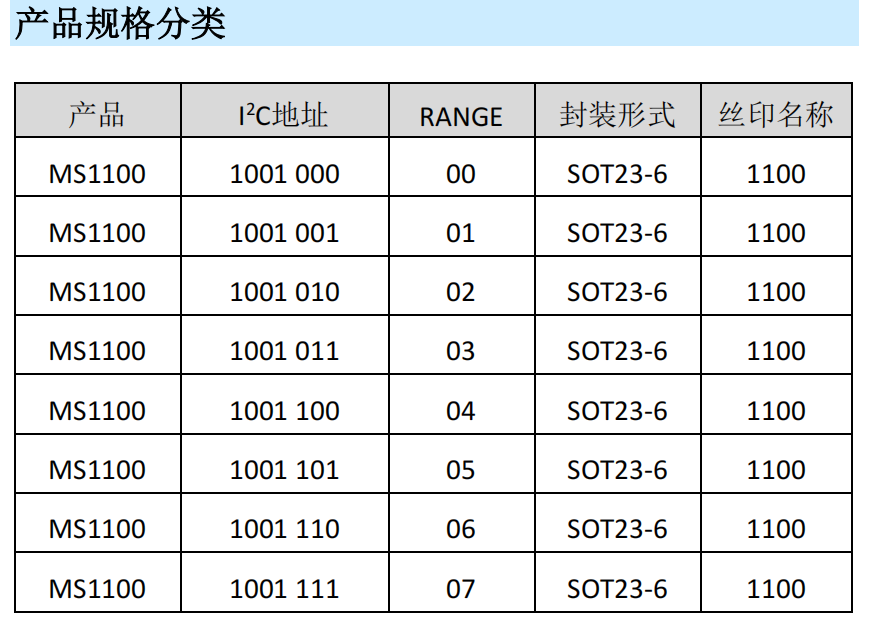

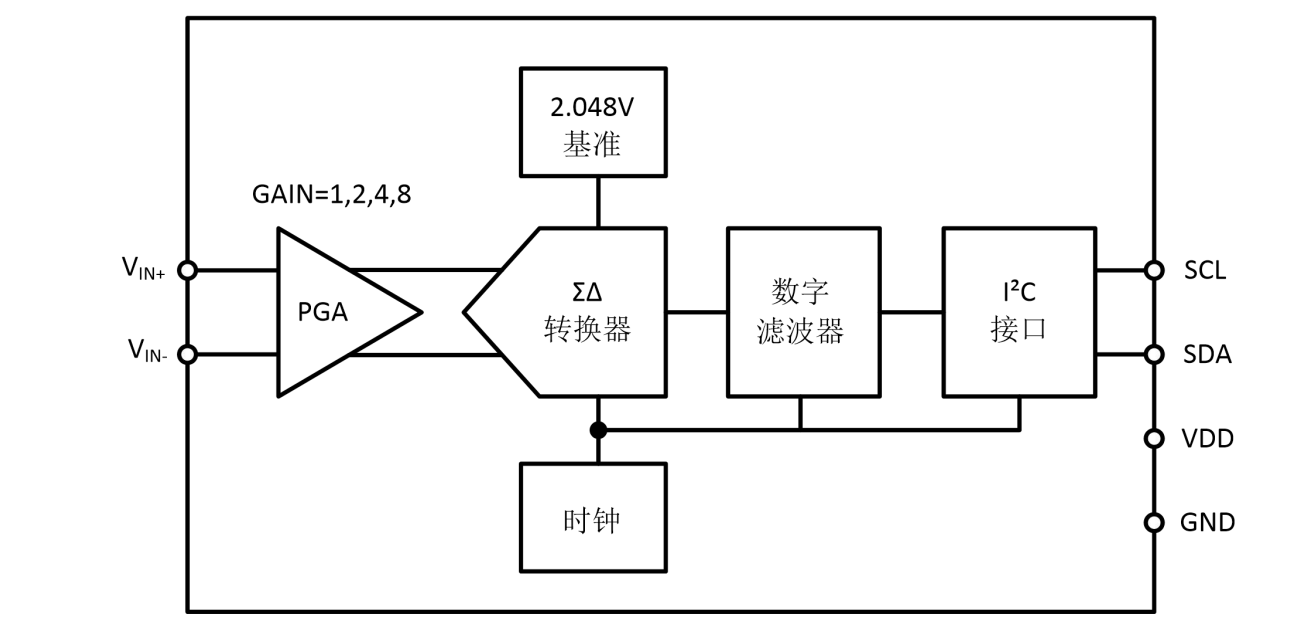

16-bit 内置基准模数转换器MS1100

在图形LCD Phidget(LCD1100)上显示天气

高精度16bit模数转换器MS1100兼容ADS1100

ET1100转换AX58100的设计要求及应用指南

ET1100转换AX58100的设计要求及应用指南

评论