Last year, shares of 3D Systems (DDD), a maker of industrial and consumer 3D printers, shot up 270 percent. These gains turned 3D Systems’ stock into one of the best performers of 2012 and broadened investor interest in 3D printing technology. The question for 2013 will be whether that interest can hold as investors, enthused by what they’ve been reading about 3D printing technology, encounter some of the realities of the marketplace for these machines.

(Folks just coming up to speed on this topic can check out a profile I wrote on 3D Systems and 3D printing early last year. Those who read it and invested can thank me later.)

3D Systems makes the vast majority of its money selling large printers to companies that want to crank out quick prototypes of parts. Aeronautics and auto companies have been longtime users of this technology. Today so, too, are consumer electronics companies and even orthodontists making custom braces. For all of 2011, 3D Systems reported revenue of $230.4 million. One chunk ($137.3 million) came from selling the actual machines, while the second chunk ($93.1 million) came from selling what amount to proprietary plastics and powders that go into the machines, much as Hewlett-Packard (HPQ) sells toner and ink to its printer customers.

STORY: Bre Pettis: 3D Printing‘s First Celebrity

Here’s the rub: 3D Systems spent just $14.3 million on research and development in 2011. That’s a paltry 6 percent of revenue. Its main rival Stratasys (SSYS) posted 2011 revenue of $155.9 million and spent $14.4 million on R&D.

Step back and think about these totals for a minute, and you might come away disheartened. 3D printing rightly gets billed as one of the most exciting areas of technology, and it’s simply not receiving the level of investment that you would expect.

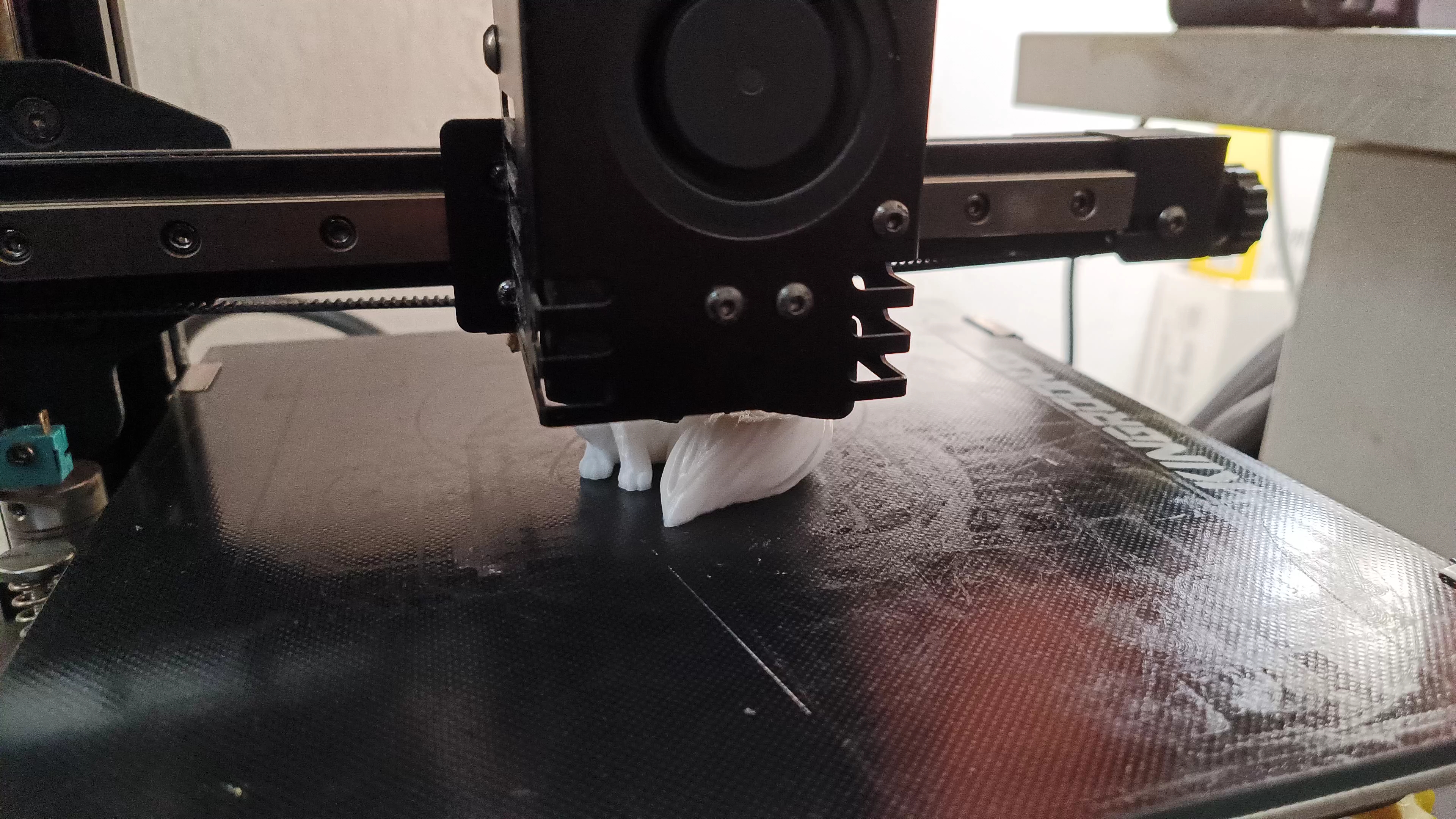

A major problem with 3D printing ignored by most is that there’s no Moore’s Law-type mechanics underlying the technology. The physics behind fusing a powder with a laser, or melting plastic and squeezing it through a nozzle, pose severe limitations on the speed at which you can print an object. And once you’ve applied a layer of plastic, the printer must take time to move and adjust a platform supporting the object.

You can add a nozzle or two to speed up the work, but this is a far cry from doubling the amount of transistors on a chip every 18 months, or doubling the storage on a hard drive. There may come a spectacular advance to change these equations, but no one seems to have found any yet. And it seems unlikely that the amount spent on R&D today by the major makers of 3D printers—3D Systems, Stratasys, and Germany’s EOS—will be enough to turn up an unexpected, exponential price-per-performance booster.

Evidence of just how antiquated the technology is can be seen at 3D Systems’ headquarters in South Carolina. There the company has dozens of machines lined up to receive orders from customers via its 3D-printing service arm. Technicians stand in front of computers and try to figure out which products can be printed together most efficiently. It’s basically just as fast to print lots of things as it is to print one thing, so you want to line up products that can fit geometrically alongside each other and maximize the amount of printing done per run.

Much of this process is done manually, with technicians twisting objects around on a screen to see how they fit together. When the actual print is complete, the technicians carry the parts back to a different room to manually clean them off and manually pack them. STORY: Howie Choset, Robot-Snake Charmer

To the extent that there are big price/performance advances taking place today, they are happening at such companies as Shapeways. Based in New York, the company operates about 10 3D printers at factories in Europe and the U.S. People go to its website, pick objects they want, and Shapeways prints them and mails them. The company has developed its own algorithms to automate how products are arranged in the 3D printers and has more automated shipping systems. “The manual process that used to take one technician two to three hours now takes place in the background,” says Peter Weijmarshausen, chief executive officer at Shapeways.

自动翻译仅供参考

研发的匮乏可能会扼杀3D打印淘金热

去年,3D系统(DDD),工业和消费者对3D打印机的制造商的股价上涨了270%。这些收益转向3D Systems公司的股票进入2012年表现最好的之一,在扩大3D打印技术的投资者的兴趣。 2013年的问题将是利益是否能容纳的投资者,被他们一直在阅读有关3D打印技术的热情,遇到一些对这些机器的市场的现实。

(乡亲只是来加快速度就这个话题可以检查出一个轮廓,我写的3D系统和3D打印,去年年初,那些谁读它,并投资可在以后感谢我。)

3D系统使得其钱卖大打印机希望炮制出零件的快速原型公司的绝大多数。航空和汽车企业一直这项技术的长期用户。今天又何尝不是如此,是消费电子公司,甚至做正畸牙套定制。对于所有2011年,3D Systems公司公布的收入230400000美元。一个块(137300000美元)来自销售实际机器,而第二块(93100000美元)来自卖什么的金额专有塑料和粉末的进入机器,就像惠普(HPQ)出售碳粉和墨水其打印机的客户。

故事:布雷松佩蒂斯:3D打印的第一个名人

这里的难题:3D系统只花了14300000美元研究和开发在2011年这是收入只有区区6%。它的主要竞争对手Stratasys公司(SSYS)公布2011营收155900000美元,花了14400000美元研发。

退一步,想想这些总计为一分钟,您可能会离开心灰意冷。 3D打印正确地被标榜为技术的最令人兴奋的领域之一,它只是不接受投资,你会期望的水平。

用3D打印由最容易被忽视的一个主要问题是,有没有摩尔定律型力学底层技术。融合背后的粉末用激光或塑料熔化,并通过喷嘴挤压它的物理构成上,在这你可以打印对象的速度受到严重限制。一旦你已经申请了一层塑料,打印机必须花时间来移动和调整的平台支持的对象。

您可以添加一个或两个喷嘴,以加快工作,但是这是一个相去甚远晶体管的数量每18个月翻一番一个芯片上,或硬盘驱动器上存储的两倍。有可能来一个壮观的进步改变这些公式,但似乎没有人发现任何尚未。它似乎是不可能的研发今天的3D打印机,3D系统,Stratasys公司和德国的主要制定者花在EOS-将是足以让了一个意想不到的,价格指数每性能助推器。

只是如何过时的技术,可以看出,在3D Systems公司的总部设在南卡罗来纳州的证据。目前公司拥有数十名排队通过它的3D打印服务手臂接收来自客户的订单的机器。技术人员站在电脑前,并试图找出哪些产品可以最有效地一起打印。它基本上是一样快,打印很多东西,因为它是打印的一件事,所以要排队,可以容纳几何彼此一起,最大限度地提高印刷每次运行做了多少产品。

这一流程是手工完成,与技术人员,扭曲在物体在屏幕上看到他们是如何结合在一起的。当实际打印完成后,技术人员携带件返还给不同的房间进行人工清洗并手动收拾他们。

故事:豪伊Choset,机器人耍蛇人

为了有今天发生大的价格/性能提升的程度,它们发生在这样的公司如Shapeways。总部设在纽约,公司业务在欧洲和美国人民的工厂约10 3D打印机去它的网站上,挑选他们想要的对象,Shapeways打印他们和他们的邮件。该公司已经开发了自己的算法来自动完成产品如何被安排在3D打印机并自动多运输系统。 “这本手册的过程,过去需要一名技术人员两到三个小时,现在发生在后台,”彼得Weijmarshausen,在Shapeways首席执行官说。

-

3D打印

+关注

关注

26文章

3475浏览量

107653

发布评论请先 登录

相关推荐

搭配君正主控芯片测评:创想三维物有所值,让你玩3D打印,而不是玩3D打印机

研发的匮乏可能会扼杀3D打印淘金热

研发的匮乏可能会扼杀3D打印淘金热

评论