When you‘re preparing to meet the founder and CEO of a startup that makes myoelectric prosthetics — those controlled by the electrical signals that muscles produce naturally when tensed up — you probably expect to come face-to-face with an idealist. You can almost imagine the reply when you ask the million-dollar question, “So what inspired you to help others?” Surely there’s some backstory involving a loved one losing a limb and a lifelong desire to give them back their mobility.

That‘s not the case for Genta Kondo, the co-founder and CEO of Tokyo-based Exiii. When Kondo entered Tokyo University’s Yokoi Lab, a testing ground for rehabilitation-focused robotics, he wasn‘t setting out on some idealistic mission to make the world a better place. Back in 2008, he was solely attracted to the science behind the lab’s prosthetic hands and power-assisted mobility devices.

“I was a basketball player and loved sports since I was a kid,” he tells Tech in Asia. “I had an interest in motor control — not motor as in engine, but the motor neuron, which is how the brain controls the body. In the beginning, I wasn‘t thinking about the social aspect or helping people, just the science.”

Kondo would go on to spend a year at Berkeley, eventually earning a master’s degree from Tokyo University‘s school of engineering. By the end of his tenure as a hardware researcher, he was unconvinced that robotic prosthetics would be accepted by the mainstream and adopted by amputees and those born with missing or partial limbs.

After graduating in 2011, he entered ubiquitous Japanese tech giant Sony to see if there was any true potential for bringing such devices to the mass market. Konda was sent to Sony’s now-defunct research and development division in Gotenyama — an area in Tokyo once nicknamed “Sony Town.” The firm officially exited the consumer robotics business in 2006, but Kondo was hired as a robotics researcher.

Though he admits to working on a robot — and having colleagues who had formerly worked on the AIBO robot dog and QRIO bipedal robot — Kondo says that he‘s still bound by a confidentiality agreement with Sony that prohibits him from discussing exactly what he did in Gotenyama.

Sony would have been a dream job for many, especially given the unusual amount of freedom that Kondo was afforded as someone who was essentially working undercover. While he enjoyed many aspects of the job, including an opportunity to work with an internal startup called the Mesh Project, Kondo’s heart remained with the prosthetics that he‘d tinkered with back in school.

High costs

It wasn’t until 2014 that the entrepreneurial bug swooped in and bit Kondo. Along with two friends from Panasonic, the trio sought to produce a bionic arm that disabled people would actually want to use.

Kondo‘s apathy vanished when he realized how under-utilized modern technology was in the current prosthetics market.

“According to clinicians I spoke with, about half of [arm and hand] amputees don’t use anything — they can still walk and do 90% of their daily activities,” Kondo says. “Within the other half, studies indicate that more than 90% are just using cosmetic, not functional, prosthetics.”

High cost is a major issue in the prosthetics industry, even for purely cosmetic items. The price rises exponentially when bringing sophisticated hardware into the mix, up to and exceeding JPY 1.5 million (US$12,100), according to Kondo. He realized that the burgeoning 3D printer movement was the answer. Not only could someone print parts at home for a fraction of the cost, but repairs and upgrades would also be easier and cheaper.

“3D printers have really accelerated the process of hardware development,” Kondo says. “When I was in the prototyping lab at Sony using 3D printers to make robotics components, I had a feeling they would change the hardware industry — and the world.”

Kondo and his team saw an opportunity to not only disrupt the prosthetics space, but to give actual movement, gestures, and handshakes back to those who‘ve suffered a personal tragedy or birth defect. Their startup, Exiii, was born.

Making its robotic prosthetic both functional and affordable was just one piece of the puzzle for Exiii. It also needed an appealing design. Kondo explains:

“People who’ve lost a hand or an arm generally want to hide it, that‘s why most prosthetics are made to look like skin. Our designs are different because we want people to show their disability in as positive a light as possible. Our designer wanted to integrate the warm feeling of a natural hand with a robotic look. If he had designed something completely robot-inspired, it would be too sci-fi for most people. He really took time to come up with smooth lines and curves that maintain a human aesthetic, without looking like Frankenstein.”

The group moved fast, entering the first prototype in the James Dyson Award later that year. Out of 650 entries from across the globe, Exiii was awarded second place. Suddenly, what began as a side project (each of the three members had maintained their day jobs) was attracting international attention. DMM, a Japanese internet company that offers everything from on-demand porn to English lessons — and which also happens to run a state-of-the-art coworking space for hardware startups in Tokyo — invited Exiii to join its inaugural class in November 2014. Soon, the media were paying attention to the young startup.

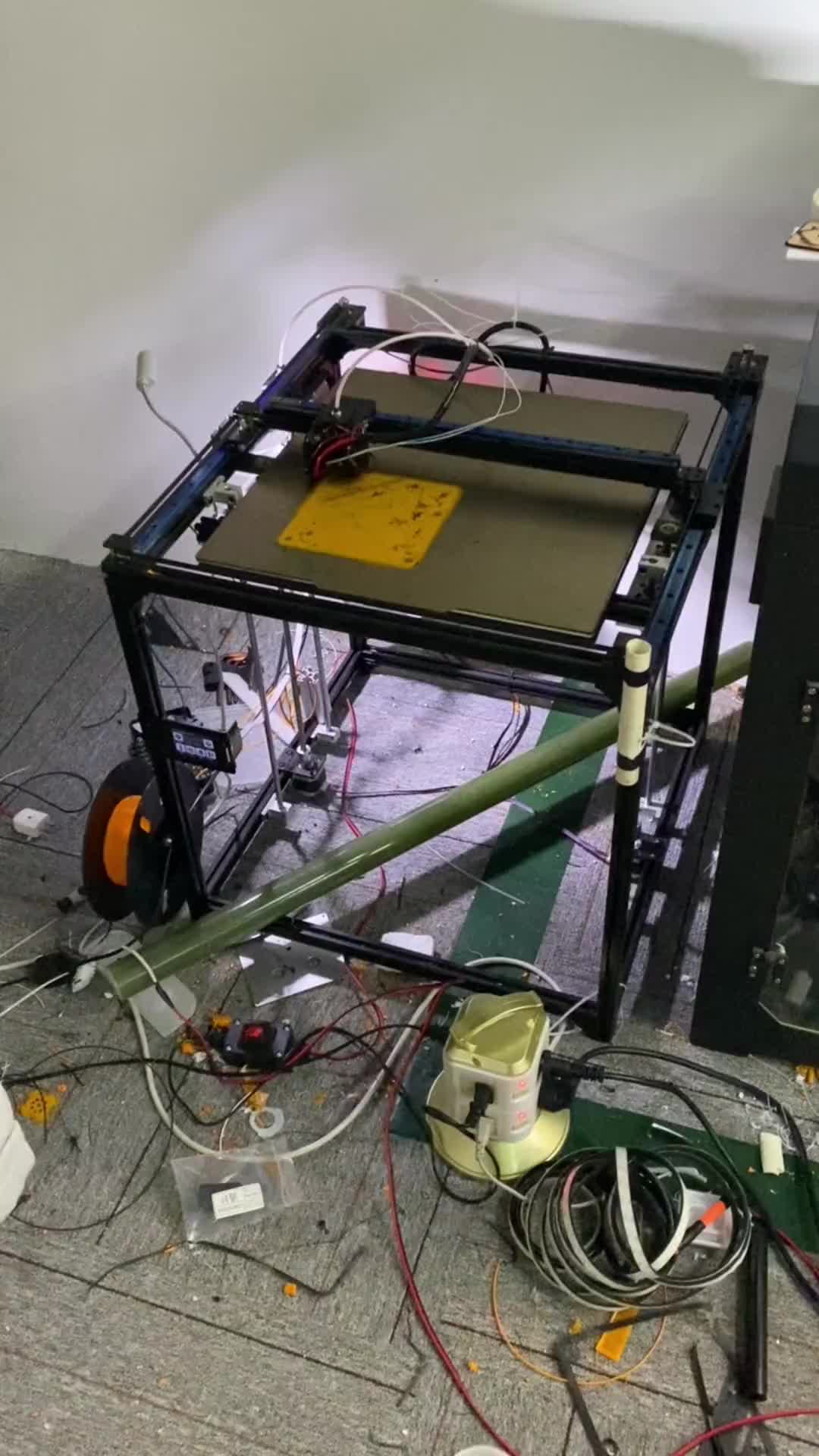

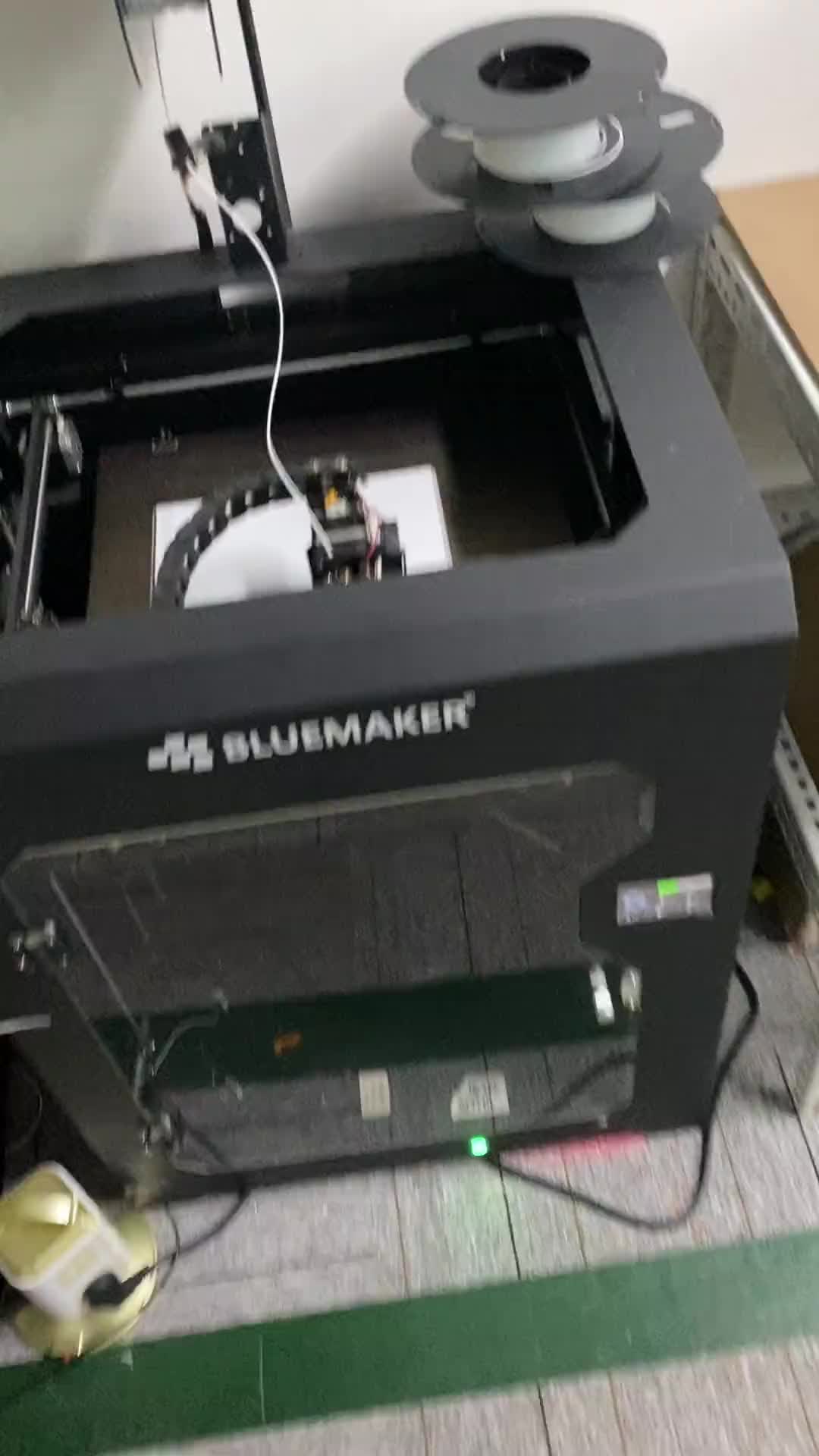

DMM.make’s hardware lab.

After being featured on a nationally-syndicated television program, Exiii found its first evangelist — or, rather, the evangelist found them. Akira Morikawa, who lost his arm in an accident in 2013, contacted the team via Facebook wanting to give it a try. The team decided that SXSW in Austin, Texas, would be as good a venue as any to show their hard work to the world.

“It‘s not strictly a medical device, but more of a wearable item,” Kondo says. “The Apple Watch is a wearable, but our prosthetic arm is the ultimate wearable.”

Function

There are currently five generations of Exiii robotic prosthetics, but it was the fourth version — dubbed “Coyote” — that stole the show at this year’s SXSW. Attendees queued up for a chance to shake hands with Morikawa, following him around the exhibition floor with curious eyes whenever he strayed from the startup‘s booth.

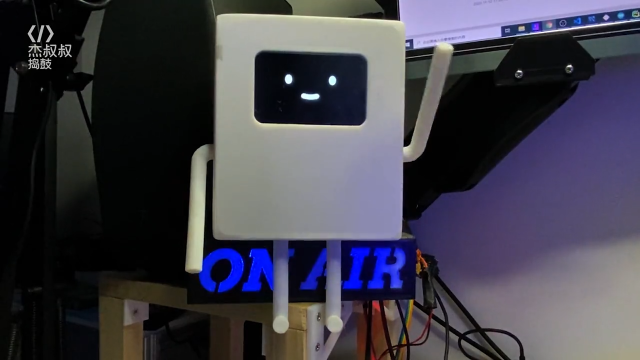

Morikawa shakes hands with a SXSW volunteer.

Coyote uses six motors — one at the base of each finger and thumb and another to rotate the thumb — and uses an Arduino Fio V3 board. Juice comes from a non-rechargeable lithium battery, which gives the arm two to three hours of continuous use. The whole package weighs about 750 grams.

“SXSW was our first-year anniversary event, and the first time to test our prototype with real users,” Kondo says. “Morikawa’s response was really great, he told us it was exactly what he was waiting for. Up until then, people were skeptical. We talked to doctors, clinicians, and therapists — conservative types [when it comes to new tech] — and they thought the design wouldn‘t satisfy the users on an emotional level.”

The startup’s fifth and latest version, “HACKberry,” is lighter and more compact than Coyote. It‘s roughly the size of an actual human hand, and thus more appealing to female users who may have felt that previous versions were too imposing. HACKberry uses an Arduino Micro, has only three motors, and features a passive wrist joint — important when a user wants to hold a drink without spilling it. Apart from reducing weight to 650 grams, fewer motors also mean vastly improved battery life of up to 12 hours, with this iteration using a popular rechargeable and easily replaceable digital camera power pack.

HACKberry can be printed with a sub-US$1,000 consumer 3D printer, like MakerBot. The entire prosthesis can be assembled at home using roughly US$300 worth of parts.

Both models connect the prosthetic to the user via a photo-reflective sensor that attaches to the residual muscle at the end of their arm. It converts muscle contractions to finger and thumb movements, which can be configured for different situations via Exiii’s companion smartphone app. Activating the index finger only, for example, allows a user to point. Activating all four fingers and the thumb is used for handshakes or holding objects.

“Coyote can grab a full bottle of water, which weighs about 500 grams,” Kondo says. “HACKberry uses even stronger motors, and is capable of pinching tiny objects like zippers or shoelaces firmly.”

Hardware that helps people

Several other high-profile robotic arm startups were born around the same time as Exiii. California-based Not Impossible Labs made headlines for “Project Daniel” in March 2014. After reading about a Sudanese boy who lost both his arms in an explosion, Not Impossible CEO Mick Ebeling illegally traveled to Sudan to build him a robotic prosthetic and teach his village how to 3D print similar prosthetics for others.

There‘s also Easton LaChappelle, the American teenager who built a brain-powered bionic arm for US$250 back in 2013. LaChappelle’s motivation came from a young girl he met at a science fair with a US$80,000 prosthesis. Because she still had many years of growing to do, the spinal-implant controlled prosthesis would have cost her family a small fortune to replace with increasingly larger sizes.

E-Nable, founded in 2013, provides free 3D-printed mechanical hands to children around the world. In the UK, Open Bionics has been providing low-cost robotic hands as an alternative to traditional prosthetics since 2014.

“None of us knew each other at first, but we all kind of appeared in late 2013 and early 2014,” Kondo says. “I think there was just a sudden trend for hardware that actually helps people.”

On June 7, Exiii embodied that sentiment when a Japanese singer (Kondo asked that her name be kept confidential for privacy reasons) took the stage with her very own HACKberry. The singer, who was born with a partial arm, used the prosthetic to wave and point at the audience — something she had been unable to do while holding the microphone in her other hand.

Open source

After a domestic crowdfunding campaign netted Exiii JPY 3.5 million (US$28,300) in late 2014, Japanese hardware incubator Abba Lab provided the startup with an undisclosed amount of seed funding this January. The startup also added an 2015 IF Design Gold Award to its mantle shortly thereafter.

DMM.make, in partnership with Abba Lab, continues to provide Exiii with office space and a US$4.5 million prototyping facility filled with 3D printers, and testing devices.

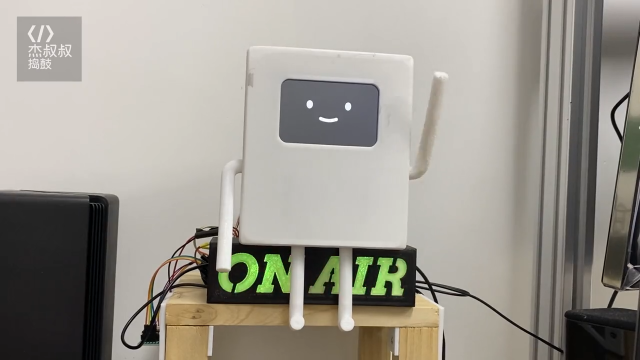

Kondo in his office at DMM.make in Akihabara。

Realizing that monetizing such a niche product would be difficult, Exiii embraced the “service model” favored by the startup‘s peers in the prosthetics space and released HACKberry’s build data on Github last month.

“The effect of going open-source has been larger than we expected,” Kondo says. “We have seen makers from around the world posting pictures of HACKberry prosthetics printed and assembled by themselves.”

In collaboration with non-profit Mission ARM Japan, the startup received JPY 25 million (US$203,000) in prize money after winning the Google Impact Challenge in March. That initiative will further the availability of Exiii‘s prosthetics for those in need.

“Our goal is to increase bionic arm penetration in Japan from 1% to 20% within three years,” Kondo says of the partnership with Mission ARM Japan, noting that less than 1% of Japanese people who could benefit from a functional prosthetic are actually using one. “It’s a shame that that number is so low, and many [within that figure] are still using tech from half a century ago. We want to spread awareness that [advanced robotic prosthetics] exist in the first place.”

Instead of charging forward with another funding round, the startup is more interested in seeing what the world will do with an open-source HACKberry.

“I want to invite makers from around the world to improve upon [it],” Kondo explains. “After SXSW, I received hundreds of emails asking to make it open source. With a small team, we couldn‘t possibly cover all the feature requests that people had made, so going open source makes a lot of sense.”

HACKberry will be entering into clinical trials in Japan to see how it holds up during daily use and how it can be tweaked for patients with different conditions. Ever the scientist, Kondo hopes to eventually publish an “Exiii thesis” for the medical and scientific community.

He may not have set out to change the world, but Kondo’s prosthetics have as good a chance as any to do just that.

Chinese drone researchers raise millions to be the Xiaomi of dronesQuiz: are you a great leader?JustRide raises funding to help Indians drive luxury cars at affordable pricesIndia funding round-up: Snapdeal, OYO Rooms, Swajal, iOrderFresh, Glowship

This article originally published at Tech in Asiahere

自动翻译仅供参考

如此精致,3D打印机械手正在改变着我们对假肢的思考方式

当你准备迎接启动,使肌电假肢的创始人和首席执行官 - 那些由肌肉产生自然的时候紧张了电信号控制 - 你可能希望来面对面地面对一个理想主义者。你几乎可以想像的答复时,你问的百万美元的问题,“那么是什么促使你去帮助别人?”当然,有一些背景故事涉及到一个心爱的人失去了肢体,并终身愿望,让他们回到自己的流动性。

这是不是跟它近藤,联合创始人东京Exiii和CEO的情况。当近藤进入东京大学的横井实验室,试验场康复为重点的机器人,他并没有制定出一些理想主义的使命是让世界变得更美好。早在2008年,他被完全吸引到后面的实验室的假肢手和动力辅助移动设备的科学。

“我是一个篮球运动员和喜爱的运动,因为我还是个孩子,”他告诉科技在亚洲。 “我有兴趣在电机控制 - 没有马达的发动机,但运动神经元,这是大脑如何控制身体在开始的时候,我并没有考虑过社会方面或帮助的人,只是科学。 “

近藤还要再花一年伯克利分校,最终赢得从工程的东京大学的学校的硕士学位。由他担任硬件研究结束时,他不相信机器人假肢将被主流所截肢者接受和采纳和那些天生缺失或部分肢体。

毕业,2011年后,他进入无所不在的日本高科技巨头索尼,看看是否有任何真正的潜力,使这样的设备推向大众市场。垦田被送到索尼的现已解散的研究和开发部门在御殿山 - 面积在东京曾经绰号“索尼镇”。该公司正式退出了消费类机器人业务在2006年,但近藤被聘为机器人研究员。

虽然他承认自己工作的一个机器人 - 并有谁曾以前工作过的AIBO机器狗和QRIO双足机器人的同事 - 近藤说,他仍然通过与索尼,禁止他从讨论正是他在御殿山做了保密协议的约束。

索尼就已经有很多梦想的工作,特别是考虑到自由的近藤是得到谁的人基本上是卧底工作不寻常的金额。虽然他很享受这份工作的许多方面,包括有机会与内部创业公司的网格项目工作,近藤的心脏保持与他会修补了回学校的假肢。

成本高

直到2014年,该企业的bug猛扑,咬近藤。随着松下两个朋友,三人试图制造一个仿生手臂残疾的人会真的想使用。

近藤的冷漠消失了,当他意识到充分利用现代科技是如何在目前的假肢市场。

“据医生与我交谈,大约有一半[手臂和手]的截肢者不使用任何东西 - 他们仍然可以行走,做90%的日常活动,”近藤说。 “在另一半,研究表明,90%以上的只是使用的化妆品,没有功能,假肢”。

成本高是在假肢行业的主要问题,即使是纯粹的美容项目。将在精密五金混进去,达到和超过日元150万(US $ 12,100),据近藤的价格上涨指数。他意识到,新兴的3D打印机运动是答案。不仅可能有人打印件在家里的一小部分费用,但维修和升级也将是更容易和便宜。

“3D打印机确实加快了硬件发展的过程中,”近藤说。 “当我在实验室原型索尼使用3D打印机制作机器人的组件,我有一种感觉,他们会改变硬件行业 - 与世界”

近藤和他的团队看到了一个机会,不仅扰乱了假肢的空间,而是让实际运动,手势,和握手回到那些谁已经遭受了个人的悲剧或出生缺陷。它们的启动,Exiii,就诞生了。

使得其机器人假肢既实用又实惠还只是一块拼图的Exiii的。它也需要一个有吸引力的设计。近藤解释说:

“谁已经失去了一只手或手臂人们通常想隐藏它,这就是为什么大多数的假肢是由看起来像皮肤一样。我们的设计是不同的,因为我们想向人们展示自己作为正面光尽可能残疾。我们的设计师想的自然手温暖的感觉与机器人的外观结合起来。如果他设计的东西完全机器人的灵感,那就太科幻对于大多数人来说,他真的需要时间来与流畅的线条和曲线的维护一个人的审美,不看像科学怪人。“

该集团快速移动,进入了詹姆斯·戴森奖的第一个原型那年晚些时候。出的来自世界各地的650项,Exiii荣获第二名。突然,什么开始作为一个辅助项目(每个三位成员一直保持他们的日常工作)正在吸引国际社会的关注。 DMM,日本的互联网公司,提供一切从按需色情英语课 - 并且这也恰好运行的硬件初创公司在东京的一个国家的最先进的共用工作空间的空间 - 邀请Exiii参加其就职级在2014年十一月不久,媒体都开始重视年轻启动。

DMM.make的硬件实验室。

以为特色在全国银团的电视节目后,Exiii找到了自己的第一个布道者 - 或者说,传道者发现他们。晃森川,谁失去了他的胳膊在一次事故中,2013年,通过Facebook想给它一个尝试联系了球队。该团队认为SXSW在德克萨斯州奥斯汀,是因为良好的场地作为任何展示自己的辛勤劳动给世界。

“这不是严格意义上的医疗设备,但更多的是耐磨项目,”近藤说。 “苹果手表是一种可穿戴的,但我们的假肢是最终的耐磨。”

功能

目前有五代Exiii机器人假肢,但它是第四个版本 - 被称为“土狼” - 是出尽了风头,在今年的SXSW音乐节。与会者排队,有机会握手森川,跟着他周围的展会大厅与好奇的目光,每当他从启动的展台误入。

森川握手与SXSW志愿者。

狼使用六个马达 - 分别在每个手指和拇指的基极和另一个转动拇指 - 并使用一个Arduino吸入氧浓度V3板。汁来自一个非可充电锂电池,这给臂两到三个小时的连续使用。整包重约750克。

“SXSW是我们的第一个周年活动,并在第一时间与实际用户测试我们的样机,”近藤说。 “森川的回应是真是太棒了,他告诉我们,这正是他在等待直到那时,人们都怀疑我们采访了医生,医生和治疗师 - 。保守型[当谈到新的技术 - 他们认为设计将不能满足用户在情感层面上。“

在启动的第五和最新版本,“朴树”,是更轻,比狼更紧凑。这是一个实际的人的手差不多大小,从而更吸引女性用户谁可能觉得以前的版本是太有气势。朴树使用一个Arduino微,只有三个发动机,并配有被动的腕关节 - 重要的,当一个用户要举行一个饮料不会溢出了。除了减轻重量650克,减少电机也意味着大大提高电池续航能力可达12小时,使用流行的可充电方便更换数码相机的电源组本次迭代。

朴树可以打印一个子$ 1,000美元消费者对3D打印机,就像MakerBot。整个假体可以在家里用大约300 US $值得部件进行组装。

这两种模式通过一个光反射传感器,可连接到剩余肌肉在其臂的端部连接的假肢给用户。它转换成肌肉收缩手指和拇指的动作,它可以通过Exiii的配套智能手机应用程序不同的情况进行配置。激活食指只,例如,允许用户指向。激活所有四个手指和拇指用于握手或控股的对象。

“土狼能抢到一个完整的一瓶水,重量约500克,”近藤说。 “朴树使用更强大的发动机,并且能够像捏拉链或鞋带牢牢微小的对象。”

硬件,帮助人们

其他几个高调的机械臂初创出生大约在同一时间Exiii。总部位于加州的并非不可能实验室做了标题为“项目丹尼尔”三月2014念叨苏丹男孩谁在爆炸中失去了他的胳膊之后,没有做不到的CEO米克·艾伯林非法前往苏丹为他建造机器人假肢,并教他村如何3D打印类似的假肢他人。

还有伊斯顿LaChappelle,美国小将谁建立了一个脑动力的仿生手臂US $ 250个早在2013年LaChappelle的动机来自于一个年轻的女孩,他在科学公正会见了US $ 8万假体。因为她仍然有成长做了很多年,脊椎植入假体的控制将花费她的家人一笔不小,以取代日益更大的尺寸。

E-Nable,成立于2013年,提供免费的3D印刷机械手到世界各地的儿童。在英国,开仿生学一直在提供低成本的机器人的手,自2014年替代传统的假肢。

“我们都不知道对方在第一,但我们都挺出现在2013年末和2014年初,”近藤说。 “我认为只是硬件,实际上帮助人们突然趋势。”

6月7日,Exiii体现了这一观点,当一个日本歌手(近藤问她的名字保密,隐私原因)上台与她自己的朴树。这位歌手,谁是天生的部分手臂,用假体波,并点了观众 - 这是她未能按住她的另一只手的麦克风做。

开源

经过国内集资活动在2014年年底被捕Exiii日元350万(US $ 28,300),日本硬件孵化器阿爸实验室提供的启动与种子基金今年1月金额不详。该启动还增加了2015年IF设计金奖其衣钵此后不久。

DMM.make,与阿爸实验室的合作伙伴关系,继续提供Exiii办公空间和US $ 4.5万美元的原型工厂充满了3D打印机,和测试设备。

近藤在他的秋叶原办公室DMM.make。

认识到货币化这样一个小众的产品将是困难的,Exiii接受了“服务模式”被启动的同龄人在修复空间的青睐和上个月发布的Github上朴树的生成数据。

“要去开源的效果比我们预期的更大,”近藤说。 “我们已经看到厂商从世界张贴印和组装自己朴树假肢的照片左右。”

与非营利性使命ARM日本合作,启动赢得了谷歌挑战赛的影响在三月份后,日元获得2500万美元(US $ 203,000)的奖金。这一举措将进一步Exiii的假肢的可用性为那些需要的人。

“我们的目标是增加在日本的仿生手臂渗透率从1%到20%在三年内,”近藤说,与团ARM日本的合作伙伴关系,并指出,日本民众不到1%谁可能受益于功能性假肢实际上使用一个。 “这是一个耻辱,这个数字是如此之低,许多[这个数字之内]仍在使用高科技从半个世纪前,我们要传播认识到[先进的机器人假肢]首先存在。”

而不是向前充电与另一轮融资,启动更希望看到什么,世界将做一个开源的朴树。

“我想邀请制造商从世界各地来改善[它],”近藤说。 “SXSW后,我收到数百封电子邮件,询问是否将其开源的。用一个小团队,我们不可能涵盖所有的人做了,所以打算开源使得很多意义上的功能需求。”

朴树将进入日本的临床试验,看看它是如何容纳日常使用过程中,以及它如何可以调整患者的不同情况。自从科学家,近藤希望最终公布的“Exiii论文”为医疗和科学界。

他可能还没有着手改变这个世界,但近藤的假肢有好机会作为任何能够做到这一点。

中国无人机科研人员筹集了数百万是dronesQuiz的小蜜:你是一个伟大的领袖JustRide提高资金,以帮助印度推动豪华车以低廉的pricesIndia一轮融资行动:Snapdeal,OYO客房,Swajal,iOrderFresh,Glowship

-

3D打印

+关注

关注

26文章

3465浏览量

107643

发布评论请先 登录

相关推荐

3D打印机正在消费市场中悄然开花

让每个人享受造物乐趣?米家3D打印机值得注意的二三事

如此精致,3D打印机械手正在改变着我们对假肢的思考方式

如此精致,3D打印机械手正在改变着我们对假肢的思考方式

评论