步骤1:准备工作

如果还没有,请参阅我的其他Instructable旋转编码器阅读,以了解如何设置硬件和Arduino IDE软件。

硬件

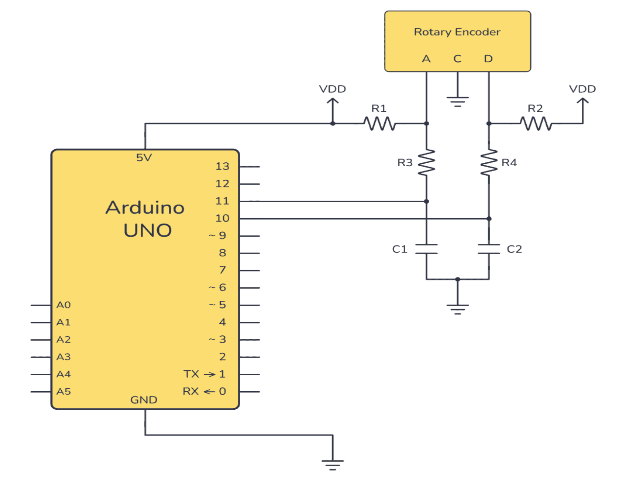

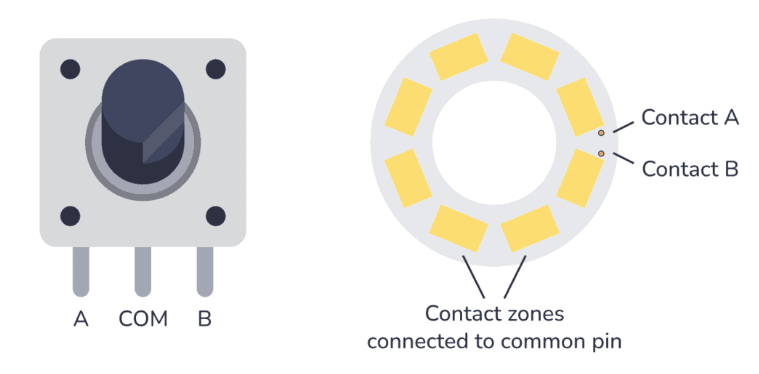

图片中显示了需要使用中心按钮的其他硬件连接。我使用Fritzing绘制了图表,但它没有代表最可能的引脚布局的旋转编码器组件,因此只需将该图表与注释结合使用,然后查看旋转编码器的照片,即可了解更多内容。可能正在寻找旋转编码器引脚布局方面的信息。

旋转编码器一侧(与具有三个引脚的一侧相对)的两个引脚之一需要接地,而另一端则要连接到Arduino的数字引脚。我已将D4用于示例草图。如果您选择其他引脚,请不要忘记更改草图中的 buttonPin 的值。

接下来是步骤2中的代码。

步骤2:代码

这是代码。通过查看结构和评论,我希望您会发现很容易适应您的特定需求!

/*******Interrupt-based Rotary Encoder Menu Sketch*******

* by Simon Merrett, based on insight from Oleg Mazurov, Nick Gammon, rt and Steve Spence, and code from Nick Gammon

* 3,638 bytes with debugging on UNO, 1,604 bytes without debugging

*/

// Rotary encoder declarations

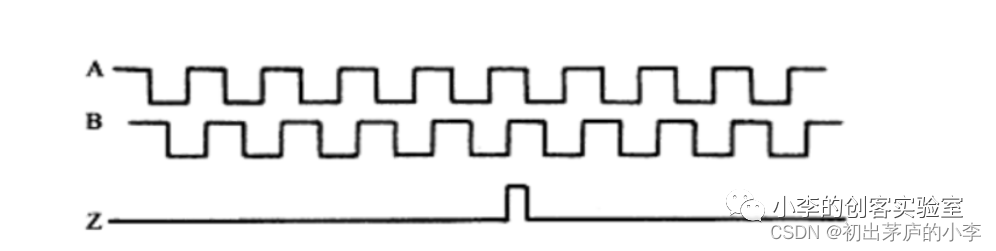

static int pinA = 2; // Our first hardware interrupt pin is digital pin 2

static int pinB = 3; // Our second hardware interrupt pin is digital pin 3

volatile byte aFlag = 0; // let‘s us know when we’re expecting a rising edge on pinA to signal that the encoder has arrived at a detent

volatile byte bFlag = 0; // let‘s us know when we’re expecting a rising edge on pinB to signal that the encoder has arrived at a detent (opposite direction to when aFlag is set)

volatile byte encoderPos = 0; //this variable stores our current value of encoder position. Change to int or uin16_t instead of byte if you want to record a larger range than 0-255

volatile byte oldEncPos = 0; //stores the last encoder position value so we can compare to the current reading and see if it has changed (so we know when to print to the serial monitor)

volatile byte reading = 0; //somewhere to store the direct values we read from our interrupt pins before checking to see if we have moved a whole detent

// Button reading, including debounce without delay function declarations

const byte buttonPin = 4; // this is the Arduino pin we are connecting the push button to

byte oldButtonState = HIGH; // assume switch open because of pull-up resistor

const unsigned long debounceTime = 10; // milliseconds

unsigned long buttonPressTime; // when the switch last changed state

boolean buttonPressed = 0; // a flag variable

// Menu and submenu/setting declarations

byte Mode = 0; // This is which menu mode we are in at any given time (top level or one of the submenus)

const byte modeMax = 3; // This is the number of submenus/settings you want

byte setting1 = 0; // a variable which holds the value we set

byte setting2 = 0; // a variable which holds the value we set

byte setting3 = 0; // a variable which holds the value we set

/* Note: you may wish to change settingN etc to int, float or boolean to suit your application.

Remember to change “void setAdmin(byte name,*BYTE* setting)” to match and probably add some

“modeMax”-type overflow code in the “if(Mode == N && buttonPressed)” section*/

void setup() {

//Rotary encoder section of setup

pinMode(pinA, INPUT_PULLUP); // set pinA as an input, pulled HIGH to the logic voltage (5V or 3.3V for most cases)

pinMode(pinB, INPUT_PULLUP); // set pinB as an input, pulled HIGH to the logic voltage (5V or 3.3V for most cases)

attachInterrupt(0,PinA,RISING); // set an interrupt on PinA, looking for a rising edge signal and executing the “PinA” Interrupt Service Routine (below)

attachInterrupt(1,PinB,RISING); // set an interrupt on PinB, looking for a rising edge signal and executing the “PinB” Interrupt Service Routine (below)

// button section of setup

pinMode (buttonPin, INPUT_PULLUP); // setup the button pin

// DEBUGGING section of setup

Serial.begin(9600); // DEBUGGING: opens serial port, sets data rate to 9600 bps

}

void loop() {

rotaryMenu();

// carry out other loop code here

}

void rotaryMenu() { //This handles the bulk of the menu functions without needing to install/include/compile a menu library

//DEBUGGING: Rotary encoder update display if turned

if(oldEncPos != encoderPos) { // DEBUGGING

Serial.println(encoderPos);// DEBUGGING. Sometimes the serial monitor may show a value just outside modeMax due to this function. The menu shouldn‘t be affected.

oldEncPos = encoderPos;// DEBUGGING

}// DEBUGGING

// Button reading with non-delay() debounce - thank you Nick Gammon!

byte buttonState = digitalRead (buttonPin);

if (buttonState != oldButtonState){

if (millis () - buttonPressTime 》= debounceTime){ // debounce

buttonPressTime = millis (); // when we closed the switch

oldButtonState = buttonState; // remember for next time

if (buttonState == LOW){

Serial.println (“Button closed”); // DEBUGGING: print that button has been closed

buttonPressed = 1;

}

else {

Serial.println (“Button opened”); // DEBUGGING: print that button has been opened

buttonPressed = 0;

}

} // end if debounce time up

} // end of state change

//Main menu section

if (Mode == 0) {

if (encoderPos 》 (modeMax+10)) encoderPos = modeMax; // check we haven’t gone out of bounds below 0 and correct if we have

else if (encoderPos 》 modeMax) encoderPos = 0; // check we haven‘t gone out of bounds above modeMax and correct if we have

if (buttonPressed){

Mode = encoderPos; // set the Mode to the current value of input if button has been pressed

Serial.print(“Mode selected: ”); //DEBUGGING: print which mode has been selected

Serial.println(Mode); //DEBUGGING: print which mode has been selected

buttonPressed = 0; // reset the button status so one press results in one action

if (Mode == 1) {

Serial.println(“Mode 1”); //DEBUGGING: print which mode has been selected

encoderPos = setting1; // start adjusting Vout from last set point

}

if (Mode == 2) {

Serial.println(“Mode 2”); //DEBUGGING: print which mode has been selected

encoderPos = setting2; // start adjusting Imax from last set point

}

if (Mode == 3) {

Serial.println(“Mode 3”); //DEBUGGING: print which mode has been selected

encoderPos = setting3; // start adjusting Vmin from last set point

}

}

}

if (Mode == 1 && buttonPressed) {

setting1 = encoderPos; // record whatever value your encoder has been turned to, to setting 3

setAdmin(1,setting1);

//code to do other things with setting1 here, perhaps update display

}

if (Mode == 2 && buttonPressed) {

setting2 = encoderPos; // record whatever value your encoder has been turned to, to setting 2

setAdmin(2,setting2);

//code to do other things with setting2 here, perhaps update display

}

if (Mode == 3 && buttonPressed){

setting3 = encoderPos; // record whatever value your encoder has been turned to, to setting 3

setAdmin(3,setting3);

//code to do other things with setting3 here, perhaps update display

}

}

// Carry out common activities each time a setting is changed

void setAdmin(byte name, byte setting){

Serial.print(“Setting ”); //DEBUGGING

Serial.print(name); //DEBUGGING

Serial.print(“ = ”); //DEBUGGING

Serial.println(setting);//DEBUGGING

encoderPos = 0; // reorientate the menu index - optional as we have overflow check code elsewhere

buttonPressed = 0; // reset the button status so one press results in one action

Mode = 0; // go back to top level of menu, now that we’ve set values

Serial.println(“Main Menu”); //DEBUGGING

}

//Rotary encoder interrupt service routine for one encoder pin

void PinA(){

cli(); //stop interrupts happening before we read pin values

reading = PIND & 0xC; // read all eight pin values then strip away all but pinA and pinB‘s values

if(reading == B00001100 && aFlag) { //check that we have both pins at detent (HIGH) and that we are expecting detent on this pin’s rising edge

encoderPos --; //decrement the encoder‘s position count

bFlag = 0; //reset flags for the next turn

aFlag = 0; //reset flags for the next turn

}

else if (reading == B00000100) bFlag = 1; //signal that we’re expecting pinB to signal the transition to detent from free rotation

sei(); //restart interrupts

}

//Rotary encoder interrupt service routine for the other encoder pin

void PinB(){

cli(); //stop interrupts happening before we read pin values

reading = PIND & 0xC; //read all eight pin values then strip away all but pinA and pinB‘s values

if (reading == B00001100 && bFlag) { //check that we have both pins at detent (HIGH) and that we are expecting detent on this pin’s rising edge

encoderPos ++; //increment the encoder‘s position count

bFlag = 0; //reset flags for the next turn

aFlag = 0; //reset flags for the next turn

}

else if (reading == B00001000) aFlag = 1; //signal that we’re expecting pinA to signal the transition to detent from free rotation

sei(); //restart interrupts

}

// end of sketch!

在任何对菜单执行操作都不重要的行的每个注释的开头,我都使用了“ DEBUGGING”。如果您对菜单功能满意,则可能需要注释掉或删除这些行以缩小编译的草图尺寸。

请注意,菜单导航的关键部分是在用户滚动浏览选项和设置时反馈给用户。因此,如果您选择不包括DEBUGGING行,则可能应该使用另一个可视指示器(例如LCD文本显示器,LED),编码器输入正在导航菜单并更改设置。

如果我注释掉DEBUGGING行(注意,菜单导航仍需要一些视觉反馈),Arduino Uno的编译后代码约为1,650字节,希望在ATMEGA328P上留出足够的空间以容纳草图中更令人兴奋的部分!

转到步骤3,了解菜单系统的工作原理。

步骤3:操作和结论

操作

如果上传此草图后在Arduino中打开串行监视器,并开始转动编码器轴,则应该看到顶层菜单在子菜单/选项数中旋转您拥有(使用 modeMax 变量进行限制)。如果按中间的按钮,您会看到已选择要滚动到的模式/子菜单,现在可以自由选择要滚动浏览该子菜单中的0-255值。现在,如果您按下中央按钮,则将其设置为 setting1 或 setting2 或 setting3 等。Arduino自动并立即返回

上电后,Arduino会记住您将每个设置设置为什么,并且如果您返回子菜单以获取设置,则您已经设置了一个值到此为止,它将从您选择的最后一个值开始进行编码器调整!

结论

我着手编写一些基于草图的代码,旋转编码器导航Arduino的基本菜单。我还尝试使其具有可读性,以便与某些替代方案不同,有人可以看到菜单结构,并知道他们需要进行哪些更改才能根据自己的需要定制菜单。

此代码是基本的和通用的,专门用于演示功能,同时易于适应您自己的应用程序。它使用串行监视器作为基本的调试工具,如果您想查看代码的工作原理,也不需要单独显示。希望您发现它有用,并受到启发进行编辑,修改和改进!

责任编辑:wv

-

编码器

+关注

关注

41文章

3360浏览量

131481 -

Arduino

+关注

关注

184文章

6427浏览量

184826

发布评论请先 登录

相关推荐

差分编码器信号如何接plc

旋转编码器如何工作?如何与Arduino-HowToMechanicronics一起使用?

伺服电机编码器

什么是旋转编码器 旋转编码器的工作原理

如何设置用于旋转编码器的简单Arduino菜单

如何设置用于旋转编码器的简单Arduino菜单

评论